Product list of custom lcd

1/3

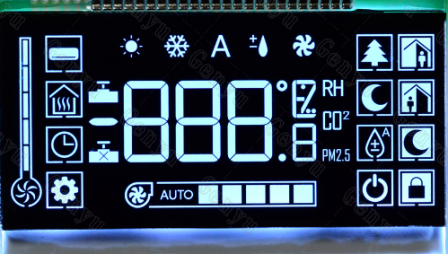

Custom segment transflective fstn lcd panel display module LCD

$4.50 - 5.40/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/4

1/4

192x64 LCD Dot Matrix Module 19264 Custom Monochrome LCD Display Module

$5.50 - 6.00/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/1

Lcd Display Manufacturer Customized Graphic Lcd Screen 7 Segment display custom Lcd

$0.30 - 2.30/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/5

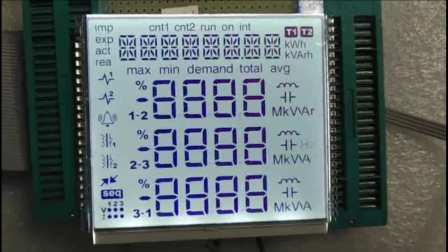

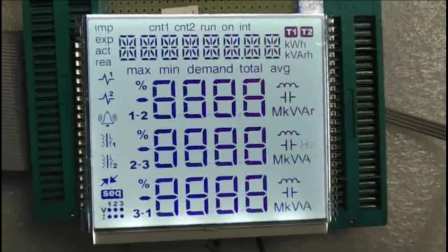

TN STN HTN FSTN VA Custom segment LCD Display Screen,Custom Energy Meter Lcd

$3.00 - 5.00/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/1

Custom monochrome 240128 240x128 t6963c module lcd graphic

$22.25 - 35.60/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/4

cheap custom 6 digit 7 segment lcd display board for fuel dispenser machine

$3.00 - 5.00/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/2

custom TIC55 TIC33 chip on glass lcd display TN reflective digit lcd for gas meter

$0.50 - 2.30/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/2

LCD manufacturer custom ODM VA HTN STN FSTN lcd display for power bank lcd screen

$0.50 - 5.00/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/2

Custom timer chronograph 4 digit lcd display with viarous backlight SMS0408G

$1.91 - 3.06/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/2

1/3

1/3

Custom 7 segment monochrome HTN/TN LCD displays for Blood Glucose Meter

$1.20 - 2.50/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/1

Custom va negative transmissive speedometer tn htn lcd dispaly screen for motorcycle

$2.50 - 4.50/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/1

Custom character type 1602 16x2 2x16 cog lcd display module

$1.90 - 2.50/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/3

SMS1706 custom 17 digit 7 segment cog smart energy meter i2c lcd display

$1.80 - 3.00/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/4

custom make 7 segment 9 digit 6 pins COG HTN lcd display panel for gas meter

$0.50 - 2.30/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

1/3

Custom OEM ODM TN metal pin lcd display for blood pressure monitor

$1.20 - 2.50/Piece

29 years in business

Changsha Sunman Electronics Co., LtdTrading Area:Global

- 1

- 2

- 3

- 4

About custom lcd

What is a custom LCD?

A custom LCD is a liquid crystal display that is specifically designed and manufactured to meet specific requirements such as size, shape, resolution, and functionality.

What are the applications of a custom LCD?

Custom LCDs are used in a wide range of electronic devices such as medical equipment, industrial control systems, military equipment, gaming devices, and consumer electronic devices.

What are the advantages of using custom LCDs?

Custom LCDs offer several advantages such as high resolution, low power consumption, high contrast ratio, and wide viewing angles. They can also be designed to fit into unique shapes and sizes, making them ideal for unconventional applications.

How are custom LCDs manufactured?

Custom LCDs are manufactured using a process called photolithography, which involves creating a pattern on a flat surface using light and chemicals. The LCD material is then deposited on top of this pattern and cut into the desired shape and size.

What is the lead time for a custom LCD?

The lead time for a custom LCD varies depending on the complexity of the design and the manufacturing process. It can range from a few weeks to several months.