Product list of corrugated machine

1/6

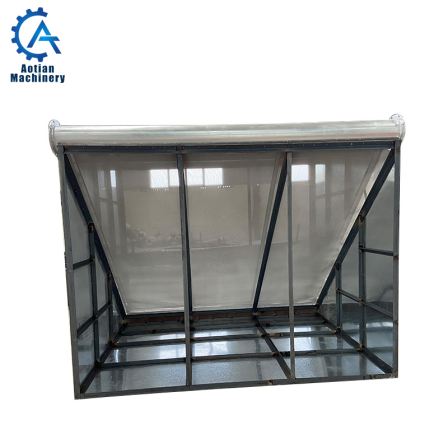

Paper product making machinery good quality corrugated cardboard carton paper machine

$30,000.00 - 750,000.00/Piece

7 years in business

Qinyang Aotian Machinery Co., LtdTrading Area:Global

1/6

Corrugated cardboard carton paper machine rotary spherical digester

$1,500.00 - 15,000.00/Piece

7 years in business

Qinyang Aotian Machinery Co., LtdTrading Area:Global

1/5

1/6

3600 corrugated paper machine

$69,000.00/Piece

24 years in business

Qinyang Xingmao Paper Machinery Co., LtdTrading Area:Global

1/6

3600 corrugated paper machine

$69,000.00/Piece

24 years in business

Qinyang Xingmao Paper Machinery Co., LtdTrading Area:Global

1/6

3600 corrugated paper machine

$69,000.00/Piece

24 years in business

Qinyang Xingmao Paper Machinery Co., LtdTrading Area:Global

1/6

3600 corrugated paper machine

$69,000.00/Piece

24 years in business

Qinyang Xingmao Paper Machinery Co., LtdTrading Area:Global

1/6

3600 corrugated paper machine

$69,000.00/Piece

24 years in business

Qinyang Xingmao Paper Machinery Co., LtdTrading Area:Global

1/6

Used corrugated paper machine equipment

$69,000.00/Piece

24 years in business

Qinyang Xingmao Paper Machinery Co., LtdTrading Area:Global

1/6

Hot selling paper product making machinery corrugated paper inclined screen for paper making machine

$300.00 - 1,500.00/Piece

7 years in business

Qinyang Aotian Machinery Co., LtdTrading Area:Global

1/6

Paper machine equipment production line carton paper recycling kraft paper machine

$75,000.00 - 750,000.00/Piece

7 years in business

Qinyang Aotian Machinery Co., LtdTrading Area:Global

1/11

- 1

- 2

- 3

- 4

- 5

- 6

- 17

About corrugated machine

What is a corrugated machine?

A corrugated machine is a machine that is used to create corrugated cardboard. The machine essentially takes rolls of paper, processes them through a series of rollers and heating elements, and then glues multiple layers together to create the final corrugated cardboard product.

What types of corrugated machines are there?

There are several types of corrugated machines, including single facers, double facers, rotary die cutters, and flexo folder gluers. Each machine is specifically designed for a different step in the corrugated cardboard process.

What is the production capacity of a corrugated machine?

The production capacity of a corrugated machine can vary greatly depending on the type of machine and its size. Some machines are capable of producing hundreds of meters of corrugated cardboard per minute, while others may only produce a few dozen meters per minute.

What are the benefits of using a corrugated machine?

The benefits of using a corrugated machine include increased efficiency and productivity, as well as the ability to create customized corrugated cardboard products to meet specific packaging needs. Additionally, using a corrugated machine can reduce waste and lower production costs in the long run.

What maintenance is required for a corrugated machine?

Maintenance requirements for a corrugated machine can vary depending on the machine’s design and manufacturer. Regular cleaning and lubrication are generally necessary to ensure smooth operation and prevent the buildup of debris or other contaminants.