Overview

Product Details

XHD Fully Automatic 1500mm PE stretch film Extrusion Machinery

HD pictures

Parameters

Item | Specs | Remarks |

Voltage/Frequency/Phase | Customized | / |

Total Installation Power | 180 KW | For the machine only. |

Consumption Power | 90 KW | For the machine only. |

Main Raw Material | LLDPE & Mpe | / |

Thickness of Film | 12-50 μm | tolerance≤±5% |

Width of the Useful Film | 1500 mm/3×500 mm | / |

Film Layer Structure | ABC or ACBCA | / |

Designed Linear Speed | 180 M/min | / |

Output | 150-250 Kg/h | / |

Dimensions (L×W×H) | 12.5×4.5×4.5 M | for ref. only |

Gross Weight | 13000 Kg | for ref. only |

Advantages

It is a very good kind of packaging material mostly used in the industrial field, port pallet packaging, building material packaging, hardware packaging etc. It enjoys the following advantages:

1) Good tensile strength.

2) Superior anti-pricking ability.

3) High transparency.

4) Good ductility and anti-impact strength.

5) Stable sticky sides etc.

Features

1. The stretch film machine alloy screw adopts special mixing function and high plasticizing design which

combine import static mixer to ensure plasticization is good, color is uniform and increase extrusion capacity

greatly.

2. Stretch film machine T-die material employs imported top special mould steel. By high precise process and

treatment to ensure the long-term use of the T-die and no deformation.. Meanwhile insures material

extrusion is more smooth and stable.

3. Stretch film machine inside cool roller adopts two-way circulation design and built-in spiral flow way to ensure

roller surface temperature is equal.

4. Stretch film machine winding station can move forth and back. Adopts advanced torque motor with four-axis

automatic tension control. Both the speed and film width arefreely adjustable.

The film produced by our machine

Optional system

1) Sub-atmospheric Vacuum Pump.

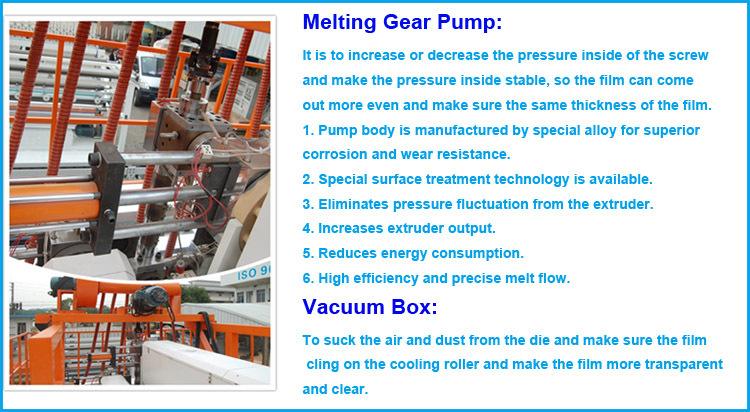

2) Melting Gear Pump and PID Control System.

3) Accurate Touchable Screen Temperature Controller.

4) Robot Hands for Roll-change and Roll-rewinding Automaticlly.

5) Including Automatic Carton Loading&Unloading.

Packing information for customer's reference

>1. Packed with stretch film;

>2. The machine is fastened to the walls of the container;

>3. Dimensions(m): 12.5*4.5*4.5 ;

>4. Gross weight: 13 T;

>5. Containers needed: 1X40 HQ+1X20 GP

Pictures of Packaging

>1. 24 hours after-sale hot line 400-833-5568.

>2. High quality stretch film recipe free sharing.

>3. 1 year warranty for all system and free technology support.

>4. Engineer dispatched to install the machine with travelling cost borne by the buyer.

Our strong sales and after-service team:

Our factory is National high-tech enterprise and got 42 patent technologies.

Our factory building area is about 30000 square meters and hold registered capital is RMB 10 Million

Our factory passed the ISO9001:2015 quality management system certification.

Our factory is National high-tech enterprise and got 42 patent technologies.

Our factory building area is about 30000 square meters and hold registered capital is RMB 10 Million

Our factory passed the ISO9001:2015 quality management system certification.

FAQs

Q: Can we make both manual grade and machine grade stretch film?

A: Yes.

Q: Can we make 5 layer stretch film by this machine?

A: Yes. You can make both 3 layer and 5 layer stretch film.

Q: Is this machine full automatic?

A: Yes. This machine is fully automatic one.

Q: Can we also use recycled material in this machine?

A: Yes. You can use recycled material. But the more recycled material you add, the stretch film will not as stretchable and transparency as the raw material one. One of our customer in Russia used 100% recycled material. Of course, the design of the screw will be a little different.

Q: What's the spare parts?

A: We have a lot of spare parts free to you. Pls email me for the list.

Q: Is there any other material that we use add to make stretch film?

A: It depends on your customers requiryment. You can add MLLDPE (metallocene) to make the film more stretchable, especially used in pallet package. Or the glue to make the film more sticky.

Q: Can you help us to install the machine?

A: Yes. We can arrange the technician to install the machine after it arrives in your factory...

Waiting for your enquiry and contact me Now!