Overview

Product Details

Screw making machine threaded rod thread rolling machine bolt thread nail and screw making machine

Product Application

screw making machine is divided into two axis rolling machine and three axis thread rolling machine

The Z28-150 Thread rolling machine for making anchor bolt is mainly used for processing precision standard parts of thread and high strength,including regular thread,trapezoid thread and modulax thread.The objective material to be processed inchcde carbon steel ,alloy steel and nonferrous metal with elongation over 10% and tensile strength less than 100kgf/mm²

1.Two spindle of the machine rotates synchronously in the same direction .Right spindle feed motion in the horizontal direction under the rolling drive.Two rolling wheels make the work as required and other thread shape by rolling.2.This machine is mainly composed of an organism, rotating box, fixed spindle seat , a movable spindle seat, hydraulic system and electrical parts etc.3.The fixed seat and the movable seat main function is installing the screw rolling wheel and adjusting the rolling wheel tooth.4.This machine is a hydraulic power system, it is mainly to make the active spindle seat to feed and return 5.The two spindle seat adjust center respectively.Angle of table axis can be adjusted in the plus or minus 3 degrees.Each shaft to feed the workpiece can be determined according to the parameters of workpiece and mechanical properties of materials.

The screw making machine can equipped the auto feeding and loading machine. pls inquiry for details.

Model | Z28-150 |

Biggest rolling dia | 56mm |

Min rolling dia | 5mm |

Main power | 5.5kw |

Hydraulic power | 2.2kw |

Dimensions | 1550*1550*1450mm |

Weight | 2000kg |

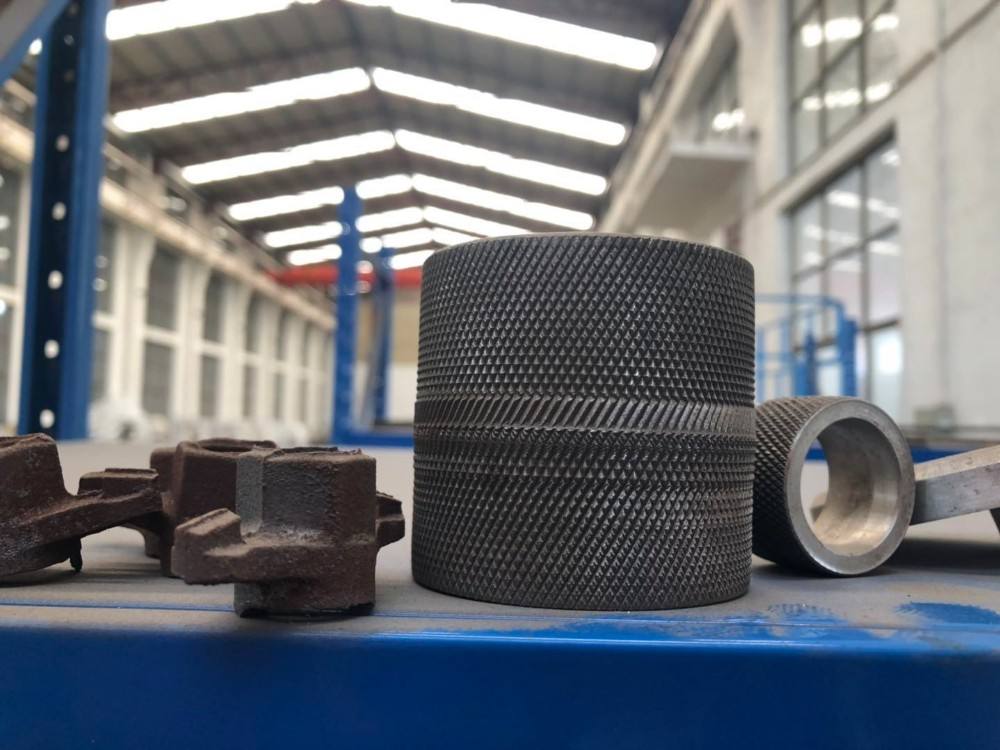

Machine Parts

Name: Thread roller

Brand: GREATCITY

Original: China

Main Features

Name: Control PanelBrand: GREATCITYOriginal: Chinamake english type for you

Working principle of screw making machine:L and R are two pairs of involute rolling wheels with the same parameters, which are installed on two spindles of the rebar thread rolling machines, and can rotate synchronously under the drive of the transmission mechanism.The R wheel can be driven by the oil cylinder for radial feed motion, and the L wheel can be adjusted by adjusting the mechanism to coincide with the indentation of the R wheel on the surface of the workpiece P. The P locate the two center hole clamping, the adjustment fixture can make the axial movement in the force around the fixture O and spindle parallel to the axis of an angle, to ensure that the workpiece in the cold rolling process and keep two rolling wheels to roll in the free state, and convenient clamping the workpiece. The structure size, geometrical tolerance and technical requirements of the rolling wheel are formulated according to the rolling wheel and cylindrical measuring gear. The length of the normal line or the cross bar distance of the rolling wheel M is calculated according to the spline data of the gear, and the required material can be Cr12MoV (hardness 59 ~ 62HRC)

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packaging | ||

Size | 1.6 (L) * 1.6 (W) * 1.5(D) | |

Weight | 2 T | |

Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. | |

1. Do you have any warranty? Yes, we have. Two years warranty on host machine is given. Six months free replacement warranty for spare parts.2. How is your after-sale service? We have a professional technology supporting team for your timely services. You can get the help you need in time by telephone, webcam, online chat (Google talk, Facebook, Skype). Please contact us once the machine has any problem. Best service will be offered.3. What certification of screw making machine do you have? All of our machines have the CE certification which ensures the quality and safety. Our machines are under strict quality management to ensure good quality. Because we fully understand that it will be a great trouble if machine have any problem during working at oversea.4. Will you teach how to use the screw making machine? Yes, we can provide a complete user manual and usage video for instruction and application. And 24/7 online consultant service ensure you whatever problem and whenever you meet, you can solve easily. It is easy to operate by anyone with the instructions.5. How about the shipment? The machine will be shipped within 2-3 days after the receipt of your payment. 6. Can visit your factory?Welcome to our factory. We would like to make invitation letter for you. Hope we can cooperate with you for a long term.

Any more request pls contact me freely, I will always online.Sales Manager Ms Kitty liuSkype: greatcity77Mobile / whatsapp / wechat : 008615512868421QQ: 694679222Email: kitty@greatcitygroup.com