Overview

Product Details

Product Description

1000L Industrial Continuous Stirred Tank Batch

chemical reactor Price

Applications: Petroleum, Chemical, Pharmaceutical, Pesticide, Food, Dye, Hydrometallurgy, etc.

Magnetic seal application: Pressure Chemical Reactions – Reactions with noxious gases – potent pharmaceuticals – zero leakage requirements—Hydrogenation reactions.

Industrial standard reactors can be used in many industrial fields, such as chemical, food, pharmaceutical, dyes and other fields. They have good sealing and safety, and are available for customization in various types. They are exported to many overseas countries and have been well received by customers.

MAIN SPECIFICATION | ||

Type | FCH1000~80,000L | |

Volume(L) | 1000~80,000L | |

Working pressure(MPa) | Negative pressure -0.1~20 | |

Working temperature(°C) | -196~350℃ | |

Stirring speed(rpm) | 0~500 | |

Motor power(KW) | 5kw~125kw | |

Heating power(KW) | 3~90 | |

Heating type | Heat oil heating, steam heating, Electric heating, Electromagnetic heating, far-infrared heating, | |

Charging type | Charging from above, discharging from bottom. | |

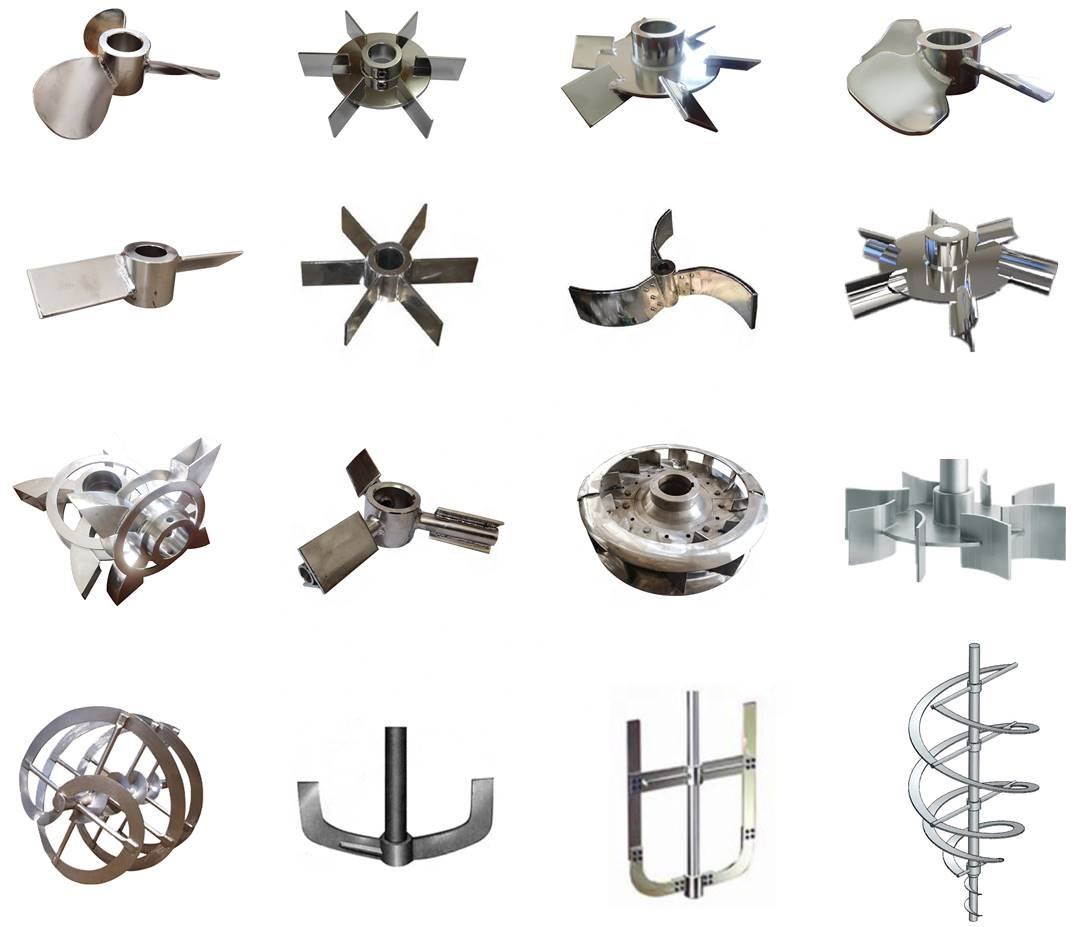

Stirring type | Customized propeller, turbine, paddle, anchor, frame, screw belt type. ...etc | |

Seal type | Magnetic seal, mechanical seal, | |

Motor | Explosion-proof motor according to customers’ requirements. | |

Construction materials (Wetted parts) | Stainless steel SUS304, SS316L, SS310S, 321, duplex steel 2205, Titanium, Nickel, Zirconium, or PTFE lining, Hastelloy C-276, C22, cladding plate. | |

Other Accessories | Condenser, storage vessel, constant pressure feed tank, receiving tank | |

Product Features

Corrossion Resistance

Metal process scope including:

*Carbon steel

*Stainless steel

*Duplex steel

*Titanium alloy

*Nickel alloy

*Hastelloy C-276

*Zirconium

*Metal clad plate

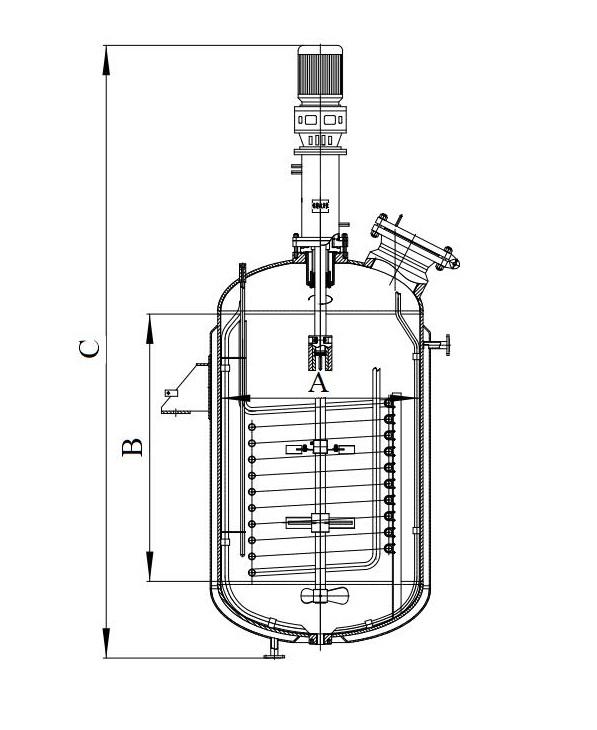

Internal Designing

Internal component design as per customer's requires, including:

*Internal condenser

*Agitator & impeller

*Dip tube

*Temperature measuring tube

*Various functional tube

*Cleaning device

*Bottom support & bearing

*Gas distributor

*Others

Opening Port

Reasonably customize the nozzle port and orientation, including:

*Manhole, liquid inlet, gas inlet, solid inlet, safety device, vent outlet... etc.

Magnetic Stirrer

* 100% Sealing. Zero leakage.

* Zero emission of hazardous fluids.* Suitable for pressure fluctuations.* Various capacities available.* Compact Design.

Agitator

*Different impeller type available for specific mixing mission.

*Special impeller design according to process condistions

Product Paramenters

Model No. | Vol. (L) | A (mm) | B (mm) | C (mm) | ||||

FCH1000 | 1000 | 1000 | 1100 | 3800 | ||||

FCH2000 | 2000 | 1200 | 1500 | 4200 | ||||

FCH3000 | 3000 | 1400 | 1700 | 4500 | ||||

FCH5000 | 5000 | 1600 | 2150 | 4700 | ||||

FCH6000 | 6000 | 1700 | 2350 | 5300 | ||||

FCH8000 | 8000 | 1900 | 2500 | 5700 | ||||

FCH10000 | 10000 | 2000 | 2800 | 5800 | ||||

FCH15000 | 15000 | 2400 | 2900 | 6100 | ||||

FCH20000 | 20000 | 2600 | 3300 | 7100 | ||||

FCH25000 | 25000 | 2800 | 3550 | 7600 | ||||

FCH30000 | 30000 | 2800 | 4350 | 9100 | ||||

Note: Larger size and specific data will be designed and confrimed according to your requires! | ||||||||

Details Images

Magnetic Coupling Stirrer

Motor & Reducer

Pressure & Leakage Test

Mechanical Seal agitator

External limpit Coils Jacket

Full Jacket

Pressure Vessel Barrel

Upper Head

Manhole

Agitator & internal cools

Tubular Coils

Serpentine Coils

Recommend Products

Customization

Customized SpecificationsIf there has special process requires, HXHCEM will also customize for you!Pls list your basis process parameters like follows:1. Reactor volume2. Operating Temperature3. Operating Pressure4. Reactor Material / contacting components material5. Agitator type, and the Mixing Speed, motor power request?6. With heating device or not? Heating type?7. Internal cooling coil or not, exchange area?8. Your other requests......Contact us!We like to help you to accomplish your plans.

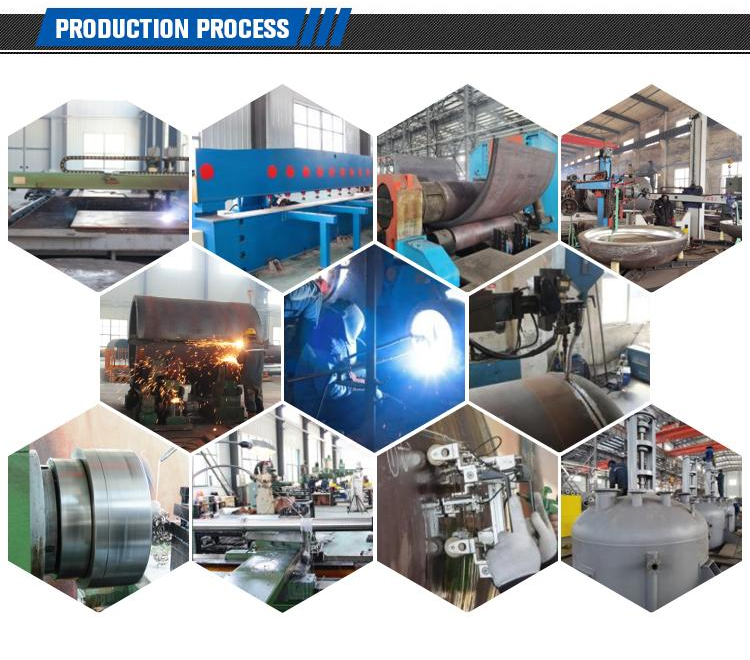

Company Introduction

Trading Area

Global