Overview

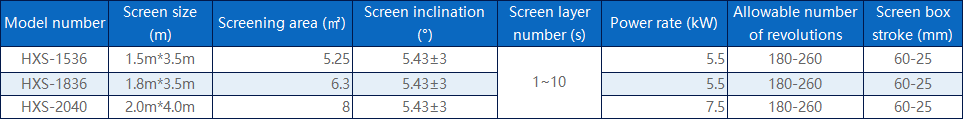

Product Details

The square swing screen, also known as the rectangular swing screen, is a high-efficiency screening equipment with high precision and large output. It has excellent self-cleaning net effect, high utilization rate of the screen, long life and good sealing effect.

Square swing sieve is widely used in chemical industry and new materials, metallurgy, metal powder, mineral powder, food, salt, sugar, abrasive, feed and other industries. Through the square swing vibrating screen, the whirling motion of the exciter is transmitted to the screen surface, so that the material is quickly dispersed in the front of the screen, so as to achieve the purpose of efficient screening.

The square swing screen adopts many new technologies and standardized design schemes, which can be combined with production conditions and different customer needs to achieve multiple combinations. At the same time, the design concept also takes into account the convenience and safety of transportation, and the overall dimensions of the equipment are designed in conjunction with transportation vehicles. The dust cover and the power transmission plate of the vibration exciter are stamped and formed by a large press at one time, which increases the strength and reduces the weight of the equipment. The plates are made of high-quality cold-rolled plates, which are more unique in mechanical design and achieve a design concept of high efficiency and energy saving. .

● Large sieve weight, unique multi-layer classification design, one machine is divided into two groups, one machine can be used for multiple machines, and the output is doubled.

● Fully enclosed structure, dust does not fly, the screen machine has low vibration and low noise, and meets environmental protection requirements.

● Flexible screening, the acceleration is 4-5 times lower than that of ordinary vibrating screens, and the service life is increased, thereby reducing maintenance costs.

● Changing the screen is more convenient, easy to operate, firm and reliable.

● Large-scale electrostatic spraying process, the equipment is more beautiful, wear-resistant and anti-rust.

● Rotary screening: Two layers of screens with the same aperture allow the material that has been screened once to be screened again to achieve higher screening accuracy.

● Rotary reverse screening: the material is screened from fine→medium-fine→medium→coarse, and coarse materials play a certain role in cleaning mesh.

1. Q: How To Order ?

A: Step 1, please tell us what model and quantity you need;

Step 2, then we will make you to confirm the order details;

Step 3, when we confirmed everything, can arrange the payment;

Step 4, finally we deliver the goods within the stipulated time.

2. After-sales Service 1 year warranty for all kinds of products;

3.Payment T/T, Western Union, Moneygram ,Escrow.

4. Transportation Transported by DHL, UPS, EMS, Fedex,Air freight. sea freight.

5. Do you support drop shipping?

Yes,your drop shipping is aviable.

Trading Area

Global