Overview

Product Details

Spot shipping cup face mask spot welding machine cup face mask machine n95 cup mask making machine

Hello, I am glad you can pay attention to our company's products. As you can see, in addition to semi-automatic cup and mask machines, our company also has fully automatic cup and mask machines. The price is subject to your actual consultation.The company has more than ten years of experience in mechanical production, and can tailor the best solution and product technology for you according to your needs. The company has experience in various fully automatic unmanned production of masks.In addition, the company also produces other types of mask machines and packaging machines. For more details, please follow the company's introduction and website homepage. We look forward to discussing cooperation with you.

Function introduction of production line

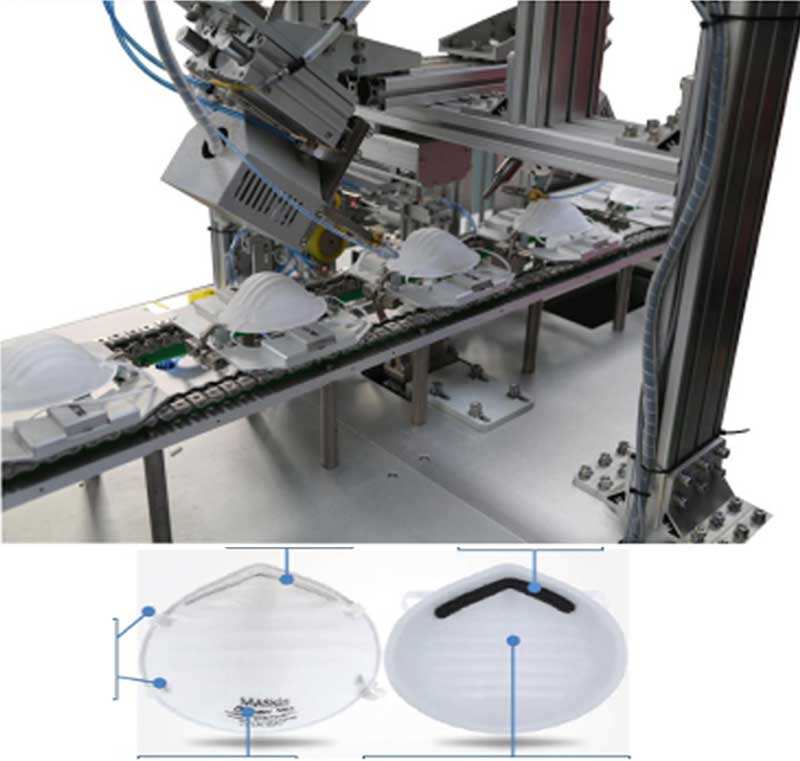

This production line is suitable for the production of cup masks. It is mainly made of non-imitation cloth, melting spray cloth, hot air foam, film, headwear rope, lock, nose bridge, etc., which can realize unmanned production (different from semi-automatic).

The automatic coat forming automatic cup production line with independent property rights is the first automatic production line for producing cup masks in China. All kinds of technology are available.

Cup masks have the following advantages over flat masks:

1. Unique cup shape design, better sealing between mask and face, dust and virus cannot leak in easily;

2. Ergonomic nose design can increase the comfort of wearing.

3. Cup masks are generally worn on the head for better comfort 4.Wear process is not easy to deformation, good protection performance.

Product pictures that can be produced

Our advantage: through the important process, the great protection melting spray cloth electrostatic protection performance

The unique process of the automatic cup mask production line with independent property rights can prevent the molten spray from being heated in the whole production process and reduce serious deformation, so that its filtration performance will not be affected.

Our other advantage: we accept all kinds of similar process mask machine customization.

product feature

1.gh stability, low failure rate, beautiful without rust

2.Meet the automatic cup mask production needs

3.The melting spray cloth is not heated in the production process, and the deformation is small

4.Meet all kinds of cup mask automatic production process, compatibility

5.The entire line can be customized

6.Operate with few or no people

7.System to achieve modular compatibility, software can be closed part of the process

8.Monitoring and detection system, maximum troubleshooting

9.PLC programming control, servo drive, high degree of automation;

10.Photoelectric detection of raw materials, to avoid mistakes, reduce waste

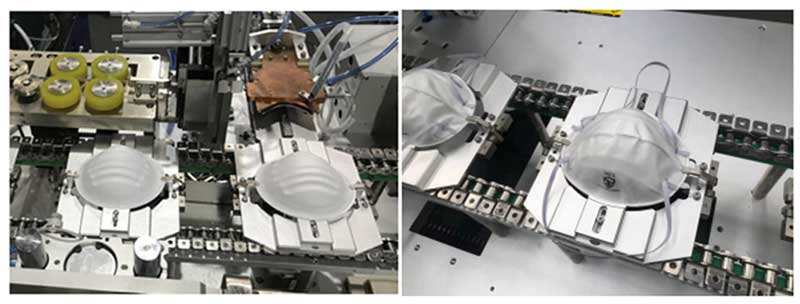

The moldingweldingcutting

Mask Forming Station

Full automatic working process for material loading, hot press cup forming, ultrasonic Cupcontour welding, Cup waste cut away, and collection of finished cups. 1.Automatic pressor control with guaranteed consistency of cup forming quality. 2.Automatic waste material detaching and collecting after dia cut. 3.With high productitivty of 12 cups per minite. 4.With 10 inches color computer operation panel. 5. The total power of Cup forming station is 9.5kw. 6.The machine equipped with emergency stops. 7.Each machine include one Cup mold, customized mold size and shape is acceptable.

Cup cover production line components

The bridge of the nose and Mask head fixed

Coating machine prepleats part

The sponge part of the mask

Mask Accessories Making Station

Automatic cut & weld the alumimum nose clips, with cut size: 90mm(length), 5mm(width), the inner side of the alumimum stip is prepared with pre-attached adhesive material. Two elastic straps staped on masks by steel nails which helps provide a secure fixing.(Optional) head elastic straps fixed by welding instead of stapling. ·Pad printing device transfers ink patterns to surface layers of masks with a printing size70mmx70mm fast and high effiency process. ·Automatic hole punching on formed cups for vavled respirators. ·Automatic exhalation valve installation and welding by ultrasoic technology. ·Sponges are installed in line

Mask Parts & Materials List:

Pad PrintingInner side of Mask Cup

|

Main Parameter

|

Configuration

|

|

Model no.

|

DEYI

|

Servo Motor

|

THINGET (France)

|

|

Product name

|

Cup mask

|

Control System

|

DEYI

|

|

Mask Size

|

140mm×120mm×50mm

|

Ultrasonic Generator

|

220V, 20kHz, 1.5kW

|

|

Speed

|

12-15 pcs/min

|

Sensor

|

Panasonic(Japan)

|

|

Material

|

Non-woven fabric, Melt-blown fabric, Hot air Cotton,Carbon fiber fabric, Mirco filter fabric, etc.

|

Air Component

|

SMC(Japan) AIRTAC(Taiwan

|

|

Layers

|

3-6

|

Belt

|

(Japan)

|

|

Hot Pressed CupType

|

Cup Type Can be Customized

|

Main Base

|

DEYI

|

|

Ear Strap Fixed Typ

|

by Stapling (Staple Size:6-7mm L; 1mm W),or by Ultrasonic Welding

|

Cable

|

IGUS(Germany) ECHU(China)

|

|

Control Panel

|

10 inches touching screen control panel

|

Cable Carrier

|

THINGET(China)

|

|

Air Pressure

|

0.6MPa

|

Linear Guide

|

SILVER(Taiwan)

|

|

Power

|

14.5kW

|

Caster

|

GLOBE (China)

|

|

Power Supply

|

380V/50Hz

|

Ball Screw

|

HIWIN(Taiwan)

|

|

Machine Area

|

13m x 2.55m x 1.8m (L x W x H)

|

Safety Device

|

SICK(Germany)

|

Company Profile

Company Profile

Shenzhen Chuangying Times Technology Co., Ltd. is a national high-tech enterprise focusing on the research and development ofautomation systems and the production of automation equipment. The company was established in 2017 and won the honorarycertificate of AAA-level enterprise, famous Chinese brand, quality inspection, national standard qualified product in 2019. Themain products are mask machines and non-standard automation equipment. We have been committed to the export business of maskmachines. The company is located in Dongguan, with a factory area of about 12,000 square meters and 122 employees.Chuangyingcurrently mainly produces mask machine types: KF94 mask machine, flat mask machine, inner ear edging mask machine, long ear maskmachine, duckbill mask machine, KN95 mask machine, 3M mask machine, non-standard customized various Shaped mask machine.Types ofpackaging machines: single-row packaging machines, pillow-type servo packaging machines, double-row packaging machines,bag-feedingpackaging machines, four-side sealing packaging machines, automatic cartoning machines and other special packaging models. The company has obtained more than 20 kinds of national new patents and software copyrights, which are in full compliance withexport standards. Chuangying has complete processing equipment and efficient technical team; with its deep technical developmentstrength, complete product guarantee system, sincere pre-sales advice and perfect after-sales service, it integratesdomestic andforeign electromechanical control technology into one. One of the automation service providers in the mask machine industry,homeappliance industry, and sensor industry provides a strong backing for the high-efficiency, high-quality, and high-precisiondevelopment of the machinery industry.

Four-side sealing packaging machine production workshopTo bag packaging machine production workshop

To bag packaging machine production workshop

Vacuum packaging shipping pictures

You are welcome to email or call for advice. Our company will serve you wholeheartedly. Honesty and pragmatism, innovation andpreciseness, quality first and service second are our company's business philosophy. I hope the epidemic situation in South Koreaand the world will end as soon as possible. I hope we can work together for win-win results

FAQ

1. How long is the delivery time?The general situation is 3-5 days for delivery. If you need a customized mask shape, it will take 7-10 days. Please refer tocustomer service for details.2. The machine I want is too ?inconsistent with what you showed on the Internet. 3.Can I do it?Yes, you need to provide machine pictures and finished mask pictures.4.what should I do if I buy a machine and Iwon’t install it back?South Korea and Vietnam have after-sales and can be installed onsite. Other countries can send installation videos and remote video guidance. Many foreign customers install this way. You onlyneed to install the four screws of the connector of the filming machine and the earband machine, learn to load the cloth andoperate normally. The company will be equipped with text version and video version of the whole teaching.5. How long is the warranty period?The warranty period is one year. The ultrasound is three months. During the warranty period, the parts are damaged and the companyprovides new parts.

After-sales service description

Hello, please don't feel strange when you see words like mine. I am the boss of this mask machine enterprise. I have been doingresearch and development of machinery and equipment for ten years. I didn't expect the sudden outbreak of the epidemic this yearto transform our company into mask machines. I have always been very strict in doing things, and so has the mask machine designedby our company. I have participated in the control of our machines from design to purchase related raw materials. Every detail ofthe machine is done with great precision. The machine runs stably and is easy to operate. There is a Korean interface. At present,plane mask machines have been made for more than 1,000 years this year, and KF94 South Korea has exported more than 200 units. Thefactory still has 100 semi-finished products in stock. Can be assembled, installed, debugged and shipped at any time. The fastestdelivery speed can be one to two days. Special custom-made mask appearance, 10 days delivery. KN95 has produced a total of 300units, and there are still 80 units in stock, which are on sale at a special price. 70-80 pcs per minute. Details can be found onthe website about the introduction of relevant machines. The KF94 packaging machine we made was followed by the machines boughtfrom South Korea and improved many shortcomings of the past machines. We are rigorous and professional in the mask machineindustry. I would like to make a special mention of South Korea's door-to-door installation service. It usually takes 10-15 daysfrom the time you place an order to the time when the goods arrive. Shipping from Qingdao port, transportation time: 3-5 days.After delivery, we will arrange the time for after-sales personnel to install in advance and train your employees how to operateone-stop service. After-sales warranty period of one year, if you have any questions, you can contact the company's after-salescustomer service in time. The company will arrange personnel to carry out on-site maintenance in the first place.

Trading Area

Global