Overview

Product Details

workshop and warehouse

Products Description

smoking machine and cold smoking machine

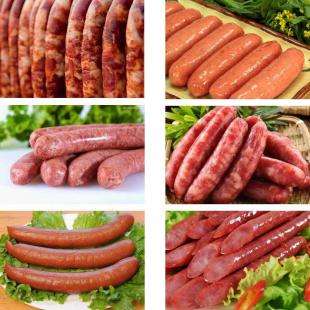

The smoker can cook and smoke various sausages, ham sausages, dry sausages, sausages, barbecue and various fish. Simple, convenient and reliable operation.

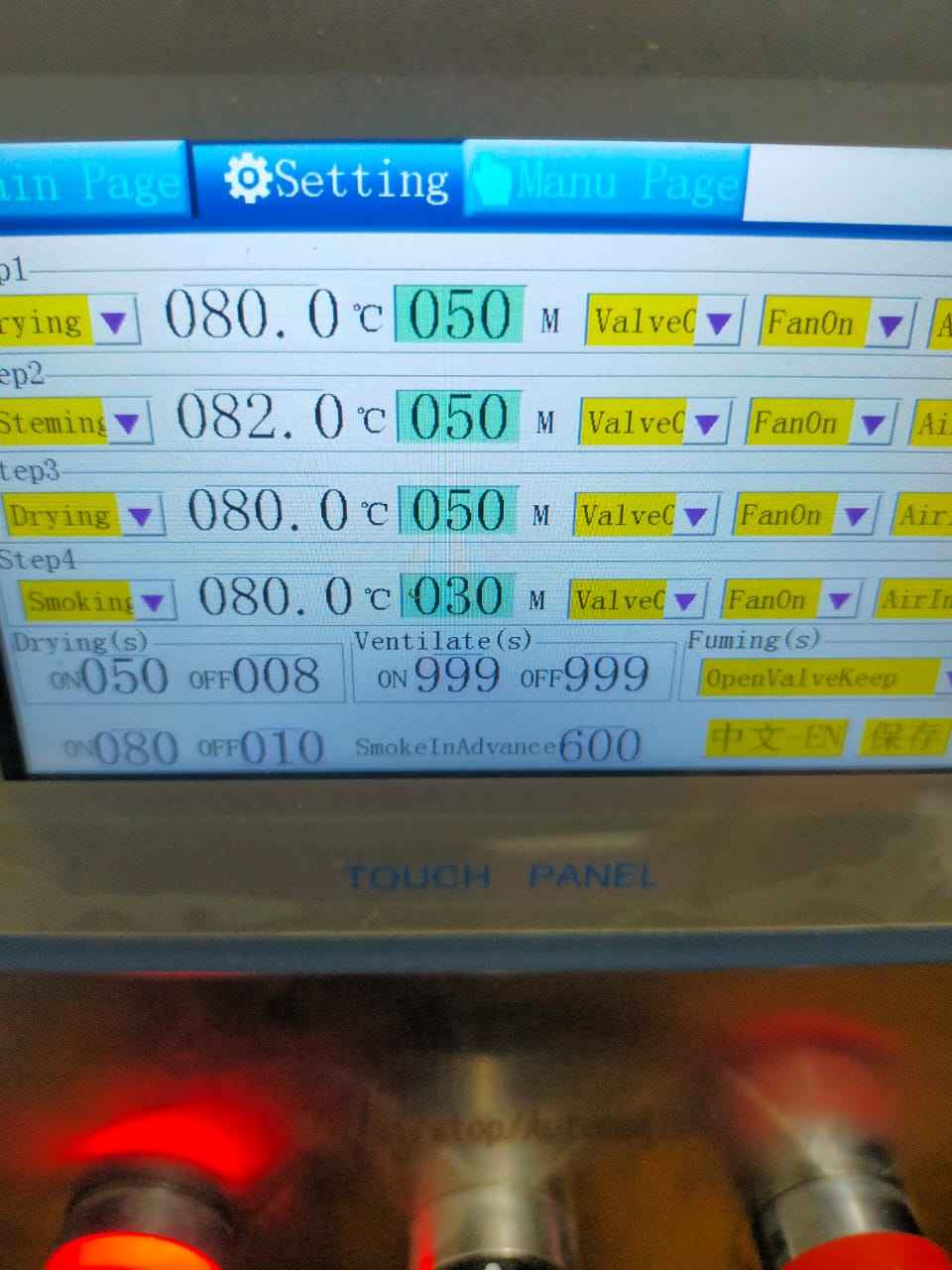

1. The machine adopts man-machine interface and PLC automatic control, with a high degree of automation.

2. This machine has the functions of electric heating or steam heating (cooking), hot air (drying or baking), smoking and exhausting. It can be freely combined according to user requirements to achieve a variety of processing techniques.

3. The smoking furnace that uses steam to heat up is generally suitable for users with boilers or equipped with steam generators.

4. The machine adopts a double-layer stainless steel structure, and the super-thick interlayer is filled with thermal insulation materials to reduce energy consumption.

5. Various process parameters (time, temperature, etc.) are displayed and controlled by the man-machine interface to ensure accuracy.

6. When the work is completed or the machine fails in the middle, it has an automatic alarm function.

7. There are two or four temperature detection probes.

3. Performance characteristics:

1. Performance:

(1), good quality and product coloring effect.

(2), stable product performance.

(3), in line with the characteristics of China's food processing industry.

(4) It is suitable for use in laboratories and small meat processing plants, and is an ideal energy-saving and environmentally friendly product.

2. Features:

(1) The full computer automatic control program can display the temperature and humidity curve graph, and when the recorder is selected, it can display the operation monitoring diagram of the executive element and the operation status table of each process.

(2) The imported air-controlled pilot steam valve controls the steam flow, the temperature control is accurate, the operation is reliable, and the temperature difference of the whole box is less than 1 °C.

(3) The fan blade is checked by dynamic balance at 2800 rpm, and the maximum wind speed can reach 25 m/s, which effectively ensures that the temperature of the product is uniform up and down and left and right during the baking process.

(4) The smoke generating device adopts a wood particle smoke generator, which has stable smoking, fast coloring, and the smoke entering the box is clean.

(5) Equipped with a high-pressure pipeline pump to clean the dirt in the coil and the flue, and equipped with nozzles of various angles in the coil and flue.

Fourth, the smoking method:

1. According to the way of smoking, it can be divided into: indirect smoking type and direct smoking type. The direct smoking method is a more traditional method, and the application and practice time is also relatively long. The indirect smoke production room is completely separate from the smoke room.

Five, structure introduction:

This machine is mainly composed of furnace body, heating system, circulating air system, and electric control system.

1. Furnace body: All internal components and outer walls of the furnace body are made of stainless steel, which is corrosion-resistant. Hang the product on the trailer, send it into the furnace body, close the furnace door, and then process such as cooking according to the set process parameters.

2. Cooking part: the interior of the furnace body is designed to automatically generate a steam system, which directly heats the products in the furnace. The output of steam can be adjusted according to different products. The pressure inside the box is not allowed to exceed 0.08Mpa.

3. Circulating air system: The top of the smoking furnace is equipped with a two-speed electric fan. The high power and large air volume ensure that the temperature in the furnace is increased, so that the temperature is uniform everywhere, and the quality of the products is stable and reliable.

4. Smoke generation system: the upper part is the saw foam box, the stirring mechanism is driven by the reducer, and the saw foam is periodically sent to the electric heater of the lower smoke generating stove, which is controlled by the smoke switch button on the electric control box, and the saw foam is heated slowly. It burns and emits smoke, and is sucked into the host by the fan to smoke the cooked food..

Smoke flow direction

Company Profile

Details Images

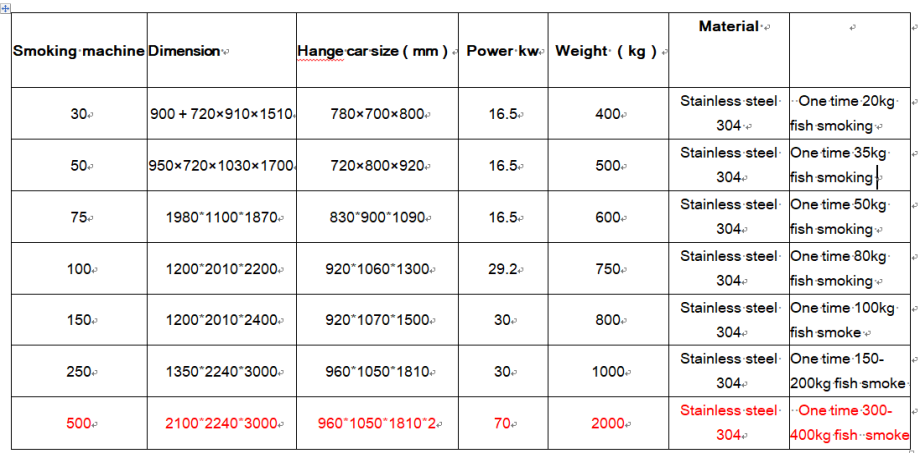

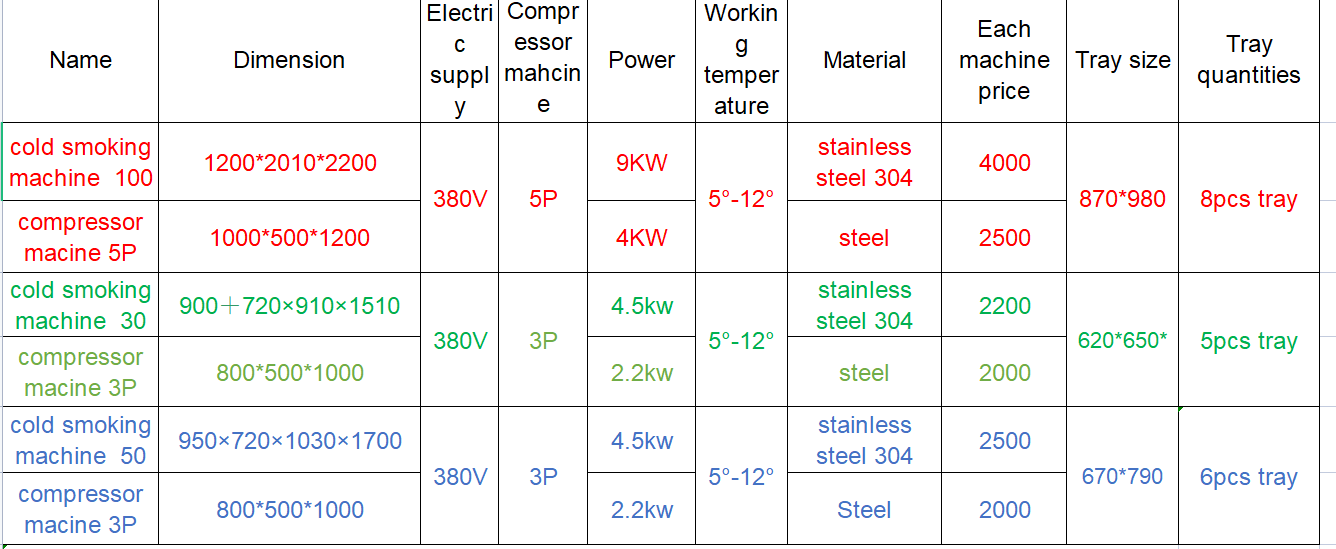

Product Paramenters

suitable range

workshop and warehouse logistic

Trading Area

Global