Overview

Product Details

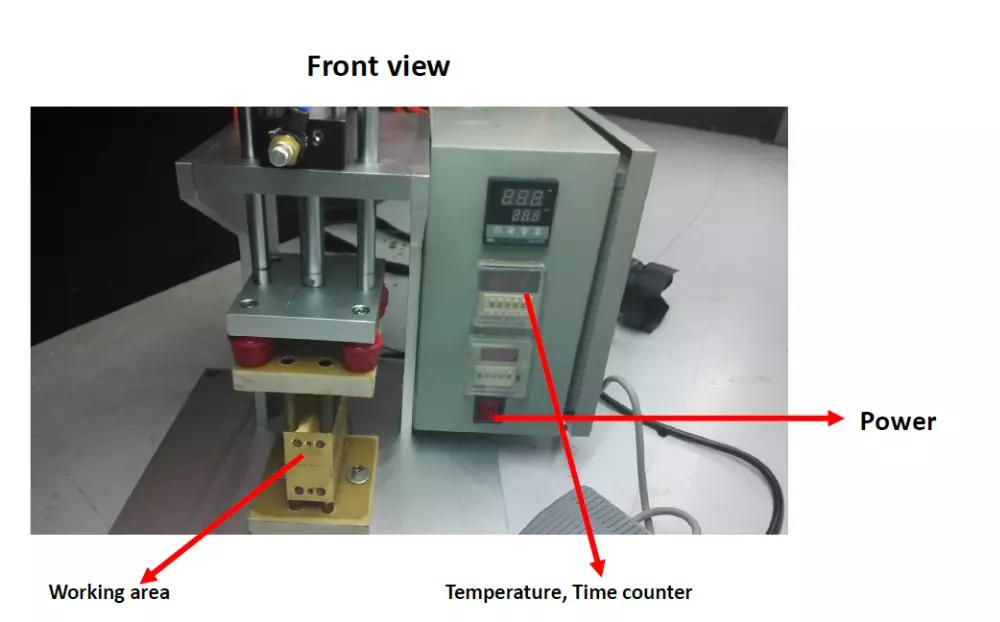

Silicone rubber o ring bonding machines

1, Automatic temperature control, time control, easy to use.

2, Fast working efficiency, stably operation system, positioning accuracy, low noise.

3, Mainly used for bonding silicone tubes, special pipe, circular tube etc.

4, International standard electrical apparatus element

Up die working area: 100mm

The Fast working frequency: 1000 times/hour

Working Air Pressure: 4-6bar

Power Input: AC220V 50Hz

1: Please read carefully the manuals before operating the machine, and new operators must pass job training tests.

2: Please check the power plug and air plug and confirm both have been connected correctly. Make sure that the earth wire is connected reliably with the device’s body, and check all components that have been installed firmly.

3: In the operation, operating the same machine at the same time by two or more people is banned.

4: In the event of abnormal operation should immediately turn off the air supply firstly, then shutting down power switch. After that, the professional must check and treat the machine

To extend service life, please maintain the equipments and confirm that they are in good condition, mainly depending on the following rules:

1: Environment: keep the working environment clean, without dust

2: Power: stable power supply, if not, voltage stabilizer will be necessarily installed on the machine.

3: Air supply: Keep the compressed air clean, without any dust, and let out the polluted water from the filtering cup regularly.

4: Keep the equipments clean, and confirm the moving part without dust interference. If not using the machine for a long time, please coat rust-proof oils on the adjusting screw rod, pack it well and arrange it properly.

5: Add the lubricating oil on the moving part of the equipment.

6: Before bonding tubes, please check the pressure and temperature of upper and lower copper-formed mould, and ensure its bonding groove clean.