Overview

Product Details

Certifications

Product Description

Dredging Pipe Float

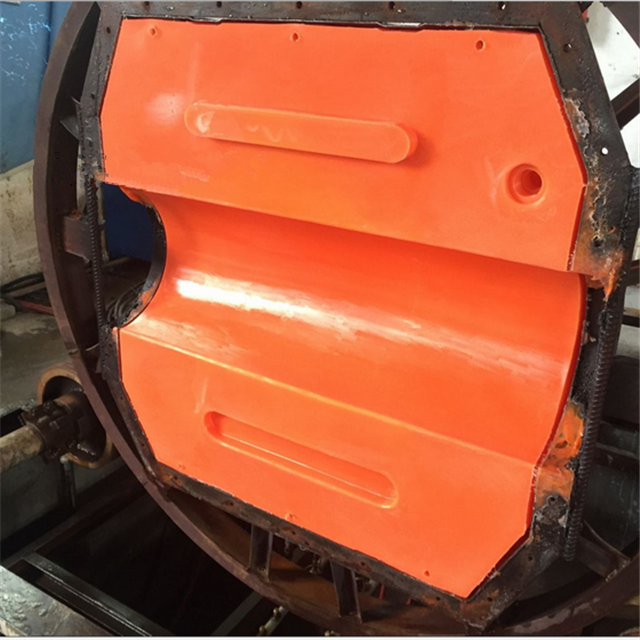

They are made up of two half-shells whose internal and external diameters and total buoyancy are adapted to demand. The floats are assembled using a hinge and stainless steel or galvanized steel screws.

The floats are filled with closed-cell eps foam with different density in base of the hydrostatic pressure the floats need to withstand.The two halves are connected each other on the pipe through four steel bolts, two each side to ensure optimal clamping with the pipe.Specification

Model | Inner Diameter (mm) | Outside Diameter (mm) | Length (mm) | Thickness (mm) | Buoyancy (kg) |

FT300*600 | 65/85/110/125 | 300 | 600 | 5 | 35 |

FT300*1000 | 30 | 300 | 1000 | 5 | 60 |

FT300*1070 | 125 | 300 | 1070 | 5 | 50 |

FT360*410 | 50 | 360 | 410 | 5 | 35 |

FT360*450 | 50 | 360 | 450 | 5 | 35 |

FT450*900 | 50/150 | 450 | 900 | 5 | 120 |

FT500*750 | 60 | 500 | 750 | 4 | 90 |

FT500*800 | 150/180/200/250 | 500 | 800 | 6 | 130 |

FT550*900 | 260 | 550 | 900 | 7 | 190 |

FT600*1000 | 40/60/100/296/300 | 600 | 1000 | 7 | 200 |

FT700*800 | 320/360 | 700 | 800 | 7 | 220 |

FT800*1100 | 50/65/400/500 | 800 | 1100 | 7 | 520 |

FT1000*1000 | 335/380 | 1000 | 1000 | 8 | 620 |

FT1050*2000 | 800 | 1050 | 2000 | 10 | 1500 |

FT1100*1100 | 500 | 1100 | 1100 | 8 | 750 |

FT1100*1400 | 220 | 1100 | 1400 | 8 | 1200 |

Application

Dredging pipeline floater is one of the most important components in the dredging operation.

The key factors for correctly selecting the floater model including the arrangement and layout of the floater, the materials to be transported, the length of the pipeline etc.

Finally to calculate the correct floater size, wall thickness, match with the high quality material selection and the filling of the inner EPS foam. All these factors ensure the safe and reliable operation of dredged pipeline.

Advantages:

High environmental protection: Made of Eco friendly food grade HDPE material.

Impact resistance: The outer casing is made of rotomolded plastic material, and the inner polyurethane foams and is resistant to impact.

Virtue:

Light weight: When the typhoon is encountered, the buoy will not be skewed.

Corrosion resistance: The buoy shell is produced one-time forming by PE material, which is resistant to acid , alkali and seawater corrosion.

Installation Instructions

Manufacturing Technique

Why Choose Us

FAQ

Q1: Do you offer a sample for testing?

A: Sure, welcome to buy our sample. According to our company policy, large order will be with better price, even return the sample fee.Q2:Can you provide detailed E-catalogue or products detail information?

A: Yes, of course. We will send the catalog and/or detailed information as you need.Q3: Shall I have a visit to your factory before placing the order?A: Welcome to visit our factory. It's better to tell us your visit plan, and the we can make an arrangement.Q4: Shall I add my logo on the product?A: Yes, we provide OEM service. But you should tell us before placing the order and send us the Trademark Authorization Letter.

Q5: How could I get the after-service?

A: We can offer the use suggestion. Every kind of products has a fixed warranty time. If there are any quality problems in the fixed quality assurance period, we can offer a new one for you.

Trading Area

Global