Overview

Product Details

Application area:

JB-750 Optical Emission Spectrometer is widely used in material analysis of various industries, such as iron and steel, non-ferrous metal, metallurgy, machinery, chemical equipment, quality inspection system and so on. It is also used in , routine identification and analysis in metallic smelt industry.

1,Manage blast furnace process control by various processes of blast furnace celerity analysis.

2,Identification of product specifications.

3,Material checking and acceptance.

4,Quality inspection.

Allocating and analyzing channel and quantitative work scale:

Major Features

1,The human oriented design, the standardized and modularized manufacture make the apparatus smaller.

2,The core components are all imported, which strengthen the stability and reliability of the apparatus.

3,We adopt the advanced foreign technologies of excitation source and design the excitation source of high energy, high stability by our own to fulfill the needs of ultrahigh content and trace analysis.

4,It adopts overall exit slit using technology which is convenient for choosing passage and regulating.

5,The high voltage of the PHT in the apparatus is controlled directly by computer and regulated by software, which improved efficiency of the passage.

6,In the apparatus, there is an automatic constant temperature system which solve the problem of bad effects to the optics system caused by changing temperature.

7,The multi-language operation software and flexible configuration enable the apparatus more humanistic.

8,This apparatus can analyze various kinds of matrix, such as Fe, Co, Ni, Ti, Cu, Al, Pb, Mg, Zn and Sn.

The configuration of the product:

Photomultiplier Tube

Main Parameters:

Excitation light source:

Supply voltage: 50Hz, 220V ± 1%

Input power: 1.0KVA

Charging capacitor: pre-combustion 8μF, exposure 1.5μF

Peak Current: pre-combustion 100A, exposure 20A

The main circuit peak pressure: 300VDC (with automatic adjustment of peak pressure)

Ignition circuit: pulse amplitude: +15 KV

Auxiliary gap: Using Tunnel Diode

Discharge frequency: 200 Hz ~ 600 Hz

Sample sets of gap: 4mm

Spectrometer:

Analysis band range: 130 ~ 650nm

Machine engraved concave grating: Curvature radius of 750mm

Depicts the density: 1667/mm

Incidence angle: 35 degrees

Allows a maximum of channels: 36 ( extend to 64 channels )

Spectrometer Local temperature: 35 °C ± 0.5 °C

Control System:

Measurement and Control System: The single board computer measurement and control, data exchange with the Host Computer

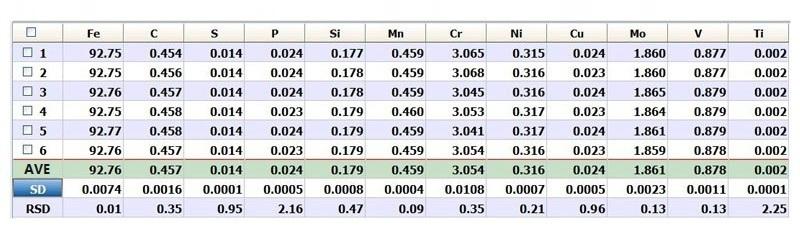

Reproducibility: RSD ≤ 0.2%

Photomultiplier tube high voltage power supply:

Stability: 8 hours is better than 0.5%

Data processing system:

1, Hardware configuration (basic configuration)

Computer: 250G/2G /19 LCD

Printer: Panasonic 1121 printer

2, Software functions

Multi-languages operation software under WINDOWS operation system

Various samples calibrate one analysis result simultaneously

Polygon and polynomial curve fitting

The concentration base of drawing curve management

Matrix correction and disturbance correction

There is a power management module

Quality controlling standard and management

System condition inspection

Data outputting management

Adjuvant Equipments (self-prepared)

Argon

1. Two cylinders of high purity argon gas. (The purity degree>99.996%)

2. One YQY-6 Oxygen reducing valve.

3. One argon gas purifier.

Power supply

1. Electronic AC Power Supply(≥3KV, single phase 220V)

2. Independent exclusive Ground line, grounding resistance less than 2Ω,

Standard samples

Analyzing different materials, choosing curve samples and controlling curves.

Environmental equipment

1. Install air conditioner according to the size of the place laid the apparatus.

2. Install dehumidifier in humid areas.

3. One small vacuum cleaner.

Apparatus installation:

1. The apparatus installation should be guided by the engineers of our company.

2. Check the goods and packing list to affirm that they are qualified and the contents match the instructions.

3. Check whether or not the lab is qualified for using the apparatus.

4. Install and start the apparatus to check if everything works well.

5. Test and adjust according to the requirements on the technical contract. Make sure that the apparatus complies with the requirements.

6. Train the users, including: operate apparatus, use software of the apparatus and daily maintenances of the apparatus.

Equipment acceptance:

Choose one or two sets of national standard samples appointed by both parties and check the equipment ,Check and analyze the precision with repeated acceptance checking program and fill the installation and acceptance checking report.

After-sales service:

1. This apparatus has a 12-month warranty since the date of install and inspection.

2. Beyond the warranty period, company will still provide after-sales service.

Spare Parts:

|

NO. |

Name |

Specification |

Qty. |

Unit |

|

1 |

Computer |

250G/2G18.5LCD |

1 |

Set |

|

2 |

Printer |

HP1108 Laser Printer |

1 |

Pcs |

|

3 |

Operating application software |

Flash U-Disk |

1 |

Pcs |

|

4 |

Apparatus operating manual |

|||

|

5 |

Protective tube |

φ6.5×45 10A |

2 |

Pcs. |

|

6 |

Tungsten electrode |

Diameter 4mm |

1 |

Pcs |

|

7 |

Polar distance gauge |

4.0mm |

1 |

pcs |

|

8 |

Sealing ring |

|

1 |

set |

|

9 |

Brush electrode |

|

1 |

pcs |

|

10 |

Stainless steel tube |

6.0mm |

2.5 |

meter |

|

11 |

Oxygen Reducing Valve |

0-0.4Mpa |

1 |

pcs |

|

12 |

Tool assembly |

|

1 |

Set |

Wuxi Jiebo Electrical Technology Co.,Ltd, located in the Yangtze River Delta, Jiangsu, Wuxi, is a modern high-tech enterprise, which professionally dedicated itself to the research, production and marketing of high-speed analytical instruments with its independent intellectual property rights. Our company owns a united and high-quality team. All the workers are of the college degree or above, and the title of engineers reach the percentage of 30%.