Overview

Product Details

Products Description

Our vision is simple but bold – we aspire to create the supply chain of the future to help our customers navigate the food machinery and to make life better for one billion people in the supply chain.

Product Features and Uses Stick noodles is a popular and unique traditional convenience food.With the development and progress of the society, the quality requirements of Fine dried noodles are getting higher and higher, and "complete equipment for Fine dried noodles production" is designed and manufactured for this purpose.The noodle processed by this complete set of equipment is widely used. It has smooth surface,neat appearance, good color, delicious taste, good cooking resistance and continuous strip.Can also be processed with different auxiliary materials out of a variety of nutritional noodles.

Features of complete equipment for noodle production line

1. Dough mixer adopts double rotation design .

2. Cutting edge is sharp and wear-resistant .

3. Equipped with high precision metal detector.

4. Feedback-controlled low-temperature drying temperature control and humidity control system .

5. Energy, low loss dry noodle cutting machine.

6. Equipped with "dry noodle breakage" recycling system .

7. Can produce a variety of different specifications of noodles.

The ropeway type low temperature hanging surface production line equipment developed by the company is made by introducing absorption technology and then reasonable development of the company itself.The equipment has reasonable design, stable performance, compact structure, convenient operation and high degree of automation.The product line is main component: alkali salt water storage tanks, additive mixer, and double shaft mixer, u-shaped or disc type curing press curing machine, composite rolling machine, tablet press, to the pole machine, automatic shelves device, low temperature drying room, under the automatic device, cut machine, noodle breakage automatic recycling equipment, surface grinder, surface first soaking pool and electric equipment etc.

Product Paramenters

Main Technical Parameters (for reference only)(Stick Noodle Production Line):

Model | Capacity | Steam Consume | Workshop dimension | Power | Workers | |||||||

(L×W×H) | (M) | (kw) | (number) | |||||||||

kg/8H | Kg/H | |||||||||||

GMS-350 | 3000 | 1000-1200 | 60*8*305 | 40 | 4 | |||||||

GMS-450 | 5000 | 1200-1400 | 65*10*3.5 | 70 | 4 | |||||||

GMS-550 | 7500 | 1300-1500 | 72*12*3.5 | 80 | 6 | |||||||

GMS-650 | 9000 | 1400-1600 | 78*13*3.5 | 95 | 6 | |||||||

GMS-800 | 11000 | 1600-1800 | 86*16*4.0 | 105 | 6 | |||||||

GMS-1000 | 15000 | 1800-2000 | 90*18*3.5 | 120 | 7 | |||||||

GMS-1200 | 18000 | 2000-2200 | 90*22*4.0 | 130 | 7 | |||||||

Ps: Not including the packing machine | ||||||||||||

Stick noodle production line product list(for reference only.The machine model will be adjusted according to the capacity.The detailed configuration is subject to the Quotation Sheet and the Specification List.)

S/N | PRODUCT NAME | MODEL | QUANTITY |

1 | ALKALI WATER TANK | YS100 | 1UNIT |

2 | Dough Mixer | HMJ100 | 1SET |

3 | Ripening Machine | XHJ100 | 1SET |

4 | Compound&Continuous Rolling Machine | MT6-30 | 1SET |

5 | Bar Feeding Machine | GT330 | 1SET |

6 | Neat Cutting Machine | ZJQ800 | 1SET |

7 | Mid-Temp Dried Device | PHF60 | 1UNIT |

8 | Multi Cutters | QF200 | 1UNIT |

9 | Electricity Control System | ZL160 | 1UNIT |

We provide CAD drawings of our products. We can customize the production line according to your actual needs.We have a team of engineers with more than 10 years of work experience to provide you with the most professional services.

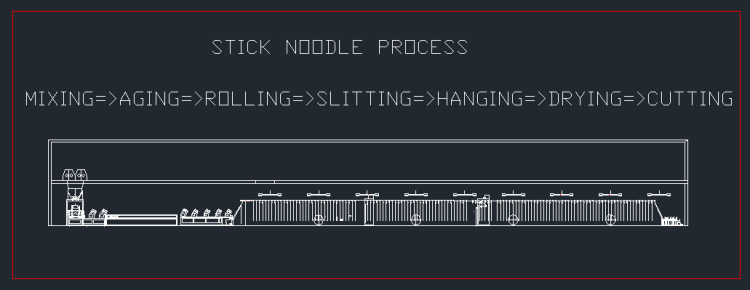

Process of the Stick Production Line

Automatic Raw Material Supply → Mixing & Measurement Of Salt And Water → Double -Shaft Double-Speed Dough Mking(Continuous Dough Kneading)→ Dough Ripening → Monolithic Rolling → Dough Sheet Aging → Continuous Rolling → Picking Out Noodles With Sticks → Automatic Elevating → Shearing → Translation Type High - Humidity Drying → Automatic Removing Off Shelves → Cutting → Packaging → Warehousing

Details Images

Product Picture

Company Profile

Guojian Machinery Manufacturing Co.,Ltd. is a professional manufacturer and exporter that is concerned with the design, development and production of noodles processing machinery. Our main products are fried instant noodles production line, non-fried instant noodles production line, vermicelli(reman)production line, dried stick noodles production line, frozen fresh noodles production line, cooked noodles production line, and so on.

Over 30 years Guojian Machinery Manufacturing Co. Ltd has been adhering to the fine artisan spirit, process design imaginative pursuit of excellence in product development and perfect, all the thing is based on product quality, and everything with excellent product quality as the premise, adhere to the belief that technology is the leading core.All the production lines are in comply with ISO,CE certificate. We also built a municipal noodle machinery research and development center. Our machine are being sold in more than 60 countries throughout the world such as Nigeria, Cambodia, India, Mexico, Ukraine, Thailand, the Philippines, Russia, Vietnam, Laos, Burma, Malaysia, Singapore, Indonesia etc.

Customer Photos

Certifications

FAQ

Q: I am a fresh man in noodles industry and without any experience .

A: The key is you must have passion only, the rest is our job : site vist,design, feasibility Report,cost analyst,deal or make

friend only,installing,training,servicing of noodle machine,free technical formula available.

Q: How about your noodle machine quality?

A: All main parts of the machine are made of 304 stainless steel. We will be responsible for site installation and commissioning.If there is anything wrong with the machine, our engineers can be on site to repair it within two days. Even if the machine.doesn't break down. We also pay a return visit twice a year by video phone.

Q: My recent noodle machine is still working but high wastage.

A: Basicly,you don't have to replace it if not extend bussibess, we do machine upgrade ,free service check.

Q: I need noodle machine spare parts.

A: We make all kinds of noodle machine spare parts: roller,slitter set, brass comb, divider,SUS304(316) mesh net, noodle casing box and cover,chain,scraper, food grade souping pallet,chain gears etc.

Q:Is it possible to visit you and see your running factory?

A: Of course , you can visit our domestic customer's noodle factory and oversea's both.

Q: I want small capacity noodle machine.

A: Available, low cost but good quality desigh for you.

Trading Area

Global