Overview

Product Details

Industrial Vacuum Emulsifier Mixer 200L Mayonnaise/Cream Homogenizer Price

Industrial emulsifier chemical vacuum blender machine means that when the materials are under the vacuum condition, it makes use of the high shear emulsifier to distributeone or several to another continuous phase rapidly and evenly. The materials will be processed in the narrow space between stator and rotor by strong energy of motion produced by the machine effect. By the operation of hydraulic sheraing, centrifugal extruding, impacting, breaking and turbulence for over 199 thousand times per minute, the materials will be disperesed and emulsifed instantly and evenly. After reciprocating circulation at high frequency, the fine finished products of stable and high quality without bubbles will be achieved.

Parameter reference

|

200l Homogenizer |

|

|

Name |

Material, name and specification |

|

Main pot |

Total volume: 260L, working volume: 200L |

|

1. inner pot |

316L stainless steel |

|

2. stir paddle,stir axis |

316L stainless steel, frame scraping stirring, mechanical seal for reaction kettle |

|

3. Mixing motor |

Power: 4kw, variable frequency speed regulation |

|

4. homogenizer |

316L stainless steel, 2800r / min, high speed mechanical seal |

|

5. Homogeneous motor |

Power 11kw |

|

6. jacket |

Stainless steel |

|

7. shell |

316L stainless steel |

|

8. lid |

316L stainless steel, sight glass hole, sight glass light hole, vacuum hole, pressure gauge hole, temperature detection hole, spice adding hole, mixing shaft hole |

|

9. Heating |

Steam heating, design pressure 0.2MPa, service pressure ≤ 0.1MPa |

|

Equipped with one 50L oil bath and one 50L water bath |

|

Application area

1. Daily Chemical & Cosmetics Industry:

such as baby cream, face cream, shaving cream, cream shampoo, toothpaste, cold cream, sunscreen cream, face cleanser, moisture cream, detergent, shampoo etc.;

2. Food Industry:

such as sauce, cheese, chocolate, cake gel, tomato paste etc;

3. Pharmacy Industry:

such as syrup, emulsion, emulsifier, ointment etc.;

4. Chemical Industry:

for chemicals mixing, heating, emulsifying, homgenizing etc.

Working principle

Precision fit of rotor and stator, claw structure of working head (rotor and stator forging manufacturing), bidirectional suction, high shear efficiency.

The intermittent high shear dispersive emulsifying homogenizer is a high-speed and stable rotation of the rotor to form high-frequency, strong peripheral tangent velocity, angular velocity and other comprehensive kinetic energy Efficiency: under the action of stator, strong and reciprocating hydraulic shear, friction, centrifugal extrusion, liquid flow collision and other comprehensive effects are formed in the reasonably narrow gap between stator and rotor. The materials work in the container repeatedly and above, and finally the products are obtained.

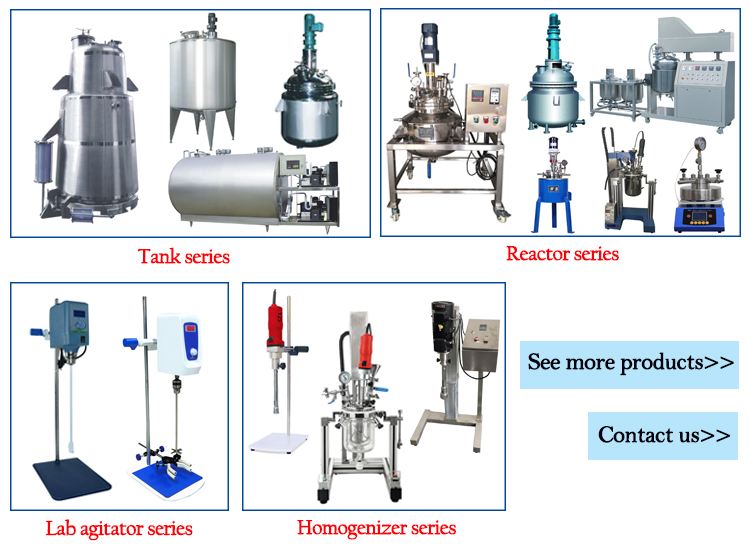

Reference picture

Where's your company? How do I get to your company?

Our company is located in Building A3, Dongtai Founder Industrial Park, No. 78 Luntou Road, Haizhu District, Guangzhou City, Guangdong Province, China. You can fly to Guangzhou Baiyun International Airport, and then we will arrange a special person to pick you up.

Are you a what type company?

We are an innovative enterprise integrating processing, manufacturing and trade.

What kind of service does it offer?

We can provide customers with common laboratory equipment and equipment and pharmaceutical, chemical industry applications of reactor tanks and supporting temperature control equipment.

How strong is your company?

Our company was founded in 2006, has its own leading brand in the country, our products sell well in China, covering most of the laboratories, deeply loved and praised by users. We have many cooperative production bases in different cities in China, concentrating the best production resources and providing the best quality products. We design a wide range of products, we have professional technical engineers, can provide customers with solution design, product customization services.

How about the quality of your products?

Product quality is not only a customer concern, but also our most important issue! We even the importance of product quality, the company has set up a strict testing system, only after strict performance testing of products, issued testing certificates can be allowed to leave the factory, you can rest assured to buy.