Overview

Product Details

The product description

QTJ4-15 manual concrete moulding price plant cost eps aac production line hydraulic hollow block making in india

Cheap price qtj4-35B brava used manual with mould paver price hollow lego ecological interlocking brick machinesworking principle of concrete block molding machine brick making

Large capacity QTJ4-15 concrete u shaped interlocking making automatic hollow maker paving machine aac block supplier.QTJ4-15 block maker machin, low frequency material feeding ,high frequency vibrating ,and pressing and vibrating both by table andmould,the concrete can be completely liquidized and air discharged wintin 2 or 3 seconds ,in order to obtain high destiny and highstrength .Full automation intelligent, manual only need 2 people, 1 person to operate PLC electric control cabinet, 1 person is responsiblefor transporting bricks.

Feartures of QTJ4-15 brick making machine

1. multi function

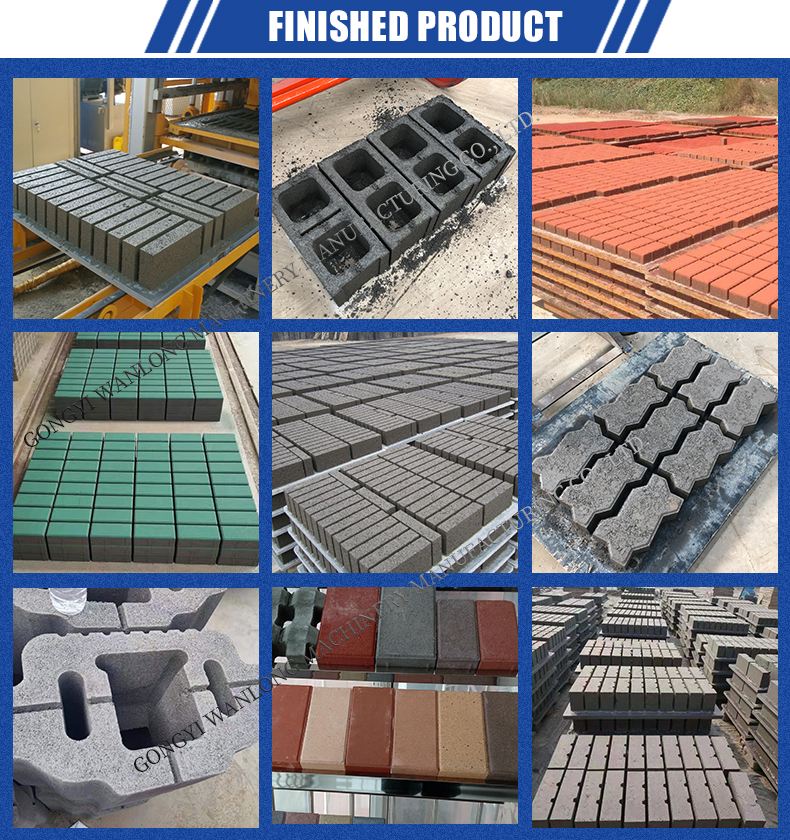

Qt4-15concrete block machine can produce various hollow blocks, solid blocks, pavers and curbs by changing molds.

2. Strong and durable, high density brick

Adopt new technology mold vibration mode to make brick., which makes the working state of brick machine more stable and efficient, and produces bricks with better quality, higher density and higher strength.

3. High quality mould

Precision wire cutting technology and carburizing treatment technology ensure longer die life.

4. Standardization

All materials and spare parts are selected according to international CE standard to ensure stable operation.

5.Spare parts

follow the machine shipment, we supply suitable wearing parts, the after-sales services will be faster.

6.Low investment and high return.

Parameter information

Basic parameters of QTJ4-15brick making machinery | ||||||||

Model | QMJ4-15 | |||||||

Power | 28KW | |||||||

Pallet size | 580*900*30mm | |||||||

Molding cycle | 15-20s | |||||||

Dimension(L*W*H) | 3600*1600*2700mm | |||||||

Host machine weight | 4800kg | |||||||

Blender

Diameter: 1.5m

Power: 11 kw

Weight: 500kg

Dimension: 1500*1500*1500mm

Conveyor belt

Model: 6m

Power: 1.5kw

Weight: 300kg

Dimension: 800*320*6000mm

FREE

The Handle of the brick cart is lengthened,

which saves manpower and makes transportation more efficient.

Stacker crane

Palletizing machine improves and realizes full automation function,Faster, more efficient.Save manpower

Block machine mould

Certification and Security

Our customer

The packing and shipping

Packing is nude package or plastic according to customer need 1. The whole brick machine production line equipment is mainly the full container sea shipping, 2. Brick machine equipment finish manufacturing and testing, next to clean up, and then do another paint protection, 3. Before shipment to use plastic film winding, wrapped the entire brick machine in case of water or moisture, 4. Then load brick machines into the container by forklift, 5. During loading to tighten the machine with reinforcement ring in container, so as to avoid the damage by transport bumps on the brick machine.

Our company

Gongyi Wanlong Machinery Manufacturing Co., Ltd.

Was established in 1996, located in Gongyi City, Henan province, is the first machinery company in Gongyi city.The registered capital is 3 million yuan. With assets of 180 million yuan, covers an area of 40,000 square meters, more than 100 employees. The company is a research and development, manufacturing, sales of automatic intelligent machinery enterprises, the main products are intelligent block forming machine, steam free raising and gas block forming machine. The products are mainly used in the production of wall block brick, road brick, permeable brick, slope protection brick, river brick, steam and air free brick andother 9 series of new environmental protection building materials.

FAQ

1.How about the quality of machines?Our machines adopt advanced technology. Moreover, we carry out strict supervision during production and make sure every finished product with high quality.

2.About the delivery time.Generally, it will be about 10-15 working days after receive your deposit, which also will be on basis of your order.3.About warranty.We provide 12 months for warranty.4.Which kind of payment is available for us?The advance deposit paid by T / T is 30%, and the balance before t / T loading is 70%. You can also choose other trading methods.5.What kind of products we can supply ?Auto concrete brick making machine, Auto hydraulic brick making machine, Free pallet automatic block forming machine,Concrete,mixer, Batching machine, Stacker, Cuber, etc.6.How to make different size and shape brick by one machine?By changing mould it can produce all types of standard building blocks.

Trading Area

Global