Overview

Product Details

plastic grain linear vibrating screen

| Model |

Screen size (L*W) (mm) |

Mesh size (mm) |

Amplitude (mm) | Layer(s) | Powder(kw) |

| DZSF-520 | 2000*500 | 4—— 10 | 1——5 layers | 2x(0.4-0.75) | |

| DZSF-525 | 2500*500 | 0.074——10 | |||

| DZSF-1020 | 2000*1000 | ||||

| DZSF-1025 | 2500*1000 | 2x(0.4-1.1) | |||

| DZSF-1030 | 3000*1000 | 2x(1.1-1.5) | |||

| DZSF-1040 | 4000*1000 | ||||

| DZSF-1235 | 3500*1200 | 2x(1.1-2.2) | |||

| DZSF-1250 | 5000*1200 | ||||

| DZSF-1535 | 3500*1500 | ||||

| DZSF-1560 | 6000*1500 | 2x(2.2-3.7) | |||

| DZSF-1845 | 4500*1800 | ||||

| DZSF-2050 | 5000*2000 | 0.074——15 | |||

| DZSF-2260 | 6000*2200 |

Working Principle

DZSF Linear vibrating screen uses double vibrating motors to drive, when two motors rotate synchronously and reversely, exciting forces generated by eccentric block are resolved in parallel to the direction of motor axis and then united as one across the motor axis direction, so its movement track is linear. There is an angle of inclination between the two motor axises relative to the screen deck. Under the influence of the resultant force of exciting force and materials itself weight, materials are thrown up to make leapfrog and linear movement forward on the screen deck in order to screen and grade the materiel. Applied in flowing line to achieve automatical operation.

Main Advantages

1. Big exciting force can provide higher casting acceleration;2. Easy to adjust screen amplitude;3. They are available in single and double deck models;4. Screen plate configuration can be adjusted according to the screen surface width;5. Exciter maintenance time is short;6. Low running noise;7. Customized sizes and designs are available.

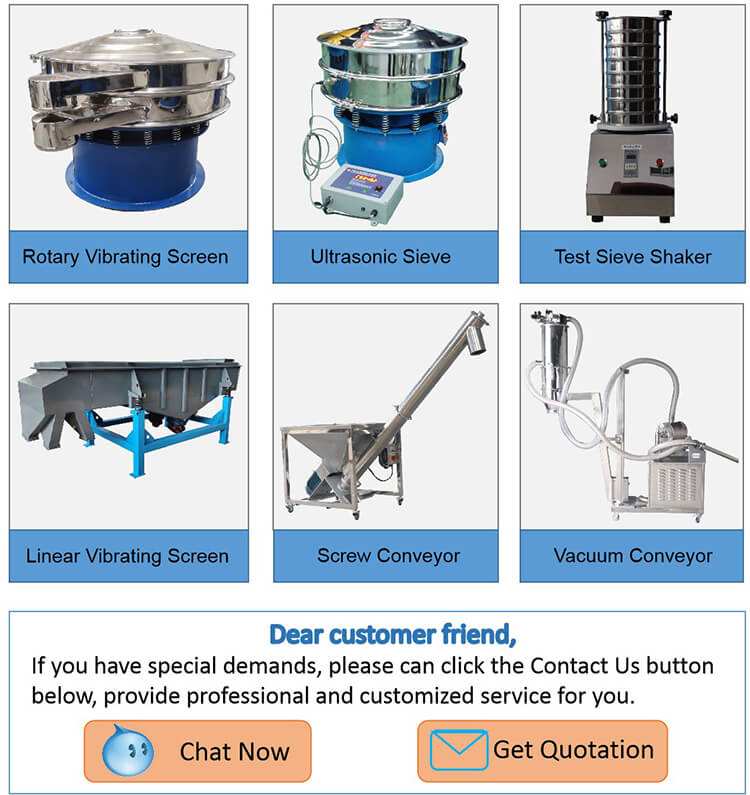

Xinxiang Dayong Vibration Equipment Co., Ltd., located in Xinxiang city, Henan province, China, which is an enterprise integrated scientific researching, device producing and product marketing. We mainly produces DY series vibrating screen, linear vibration sieve, test sieve, vibration conveyor, vibration feeder and other handling equipment.Our company mainly produces the products for sieving, conveying, elevating, and crushing equipment. Our company has strong technical force, with the strategy aiming to obtain enterprise reputation, be bold in innovative technology and provides good service, and our company has become a well-known enterprise in the industry.

Pre-sale service:a. According the user’s different needs, we work to recommend and guide for themb. To help them select the appropriate equipment

Service during sale:a. Do good communication with customers, so that each part can exchang the information.b. Deliver on time as per the contract clause.

After-sale service:a. To track the customer’s feedback after receiving the equipmentb. Do well about the work of maintenance and service

Q: How many kinds of material are supported?A. All stainless steel (304, 316L) B. All carbon steel Q235A C. Contact part Stainless steel.

Q: How to select a suitable vibrating screen?A. what’s the material and its density?B. what’s the mesh size? And which size of powder do you need?C. What’s the percentage of every size in your material?D. What’s your excepted capacity?

Q: Any self-cleaning devices on the sieving machine?Yeah, Bouncing ball, Ultrasonic system and other self-cleaning devices could be installed.