Overview

Product Details

Product Description

Structure of PUR hot melt adhesive laminating machine:

PUR hot melt adhesive compound machine equipment control adopts programmable PLC design and human-machine interface control, humanized operation, easy maintenance, tension-free discharging device, and heating circulation system, convenient to control the temperature rise and fall and stability of the glue, and laminate materials And the finished product can adopt the method of center winding or surface selection according to the needs. The gluing method is divided into two options: dot-shaped and net-shaped coating.

Specification

Working cloth width: 1600-3200 mm

Mechanical roll width: 1800-3400mm

Design line speed: 5~45 m/min

Mechanical dimensions (length * width * height): 8300×3300×3200 mm

Heat transfer oil heating temperature: adjustable hot oil circulation 200℃ (MAX)

Total mechanical power: about 40KW

Power supply: 380V 50Hz three-phase

Total equipment weight: about 7500KG

Features

1. The PUR hot melt adhesive used does not contain solvent, which is an ideal green and environmentally friendly solvent-free glue;

2. The products have no residual solvents, no emission problems in production, energy saving, and small floor space;

3. The compounding process has a wet-solid reaction, irreversible, strong adhesion and good washing fastness;

4. PUR hot melt adhesive does not contain water and solvents, does not need to be dried, and the compounding speed is fast;

5. Strong viscosity, less glue consumption and cost saving;

6. Full linkage control of the compounding process, no stretching of the base material, light and soft, and good hand feeling;

7. The heat source is oil conduction heat, fast heating, uniform heat, and energy saving;

8. The glue melting system is independent, and the glue melting is sufficiently fast;

9. Glue in dot or net pattern, the finished product has good air permeability and strong three-dimensional effect;

10. The humanized design of the machine saves operators;

11. With a small amount of diversified production design, cost-saving, the digital control system makes the operability better.

12. The pattern of the net (round) dot roller has many options, and the size and depth of the pattern can be customized according to the different requirements of customers.

Applications

Purpose of PUR hot melt adhesive laminating machine:

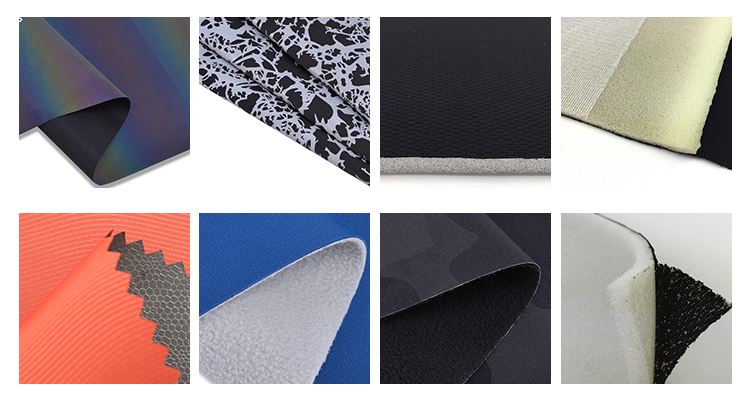

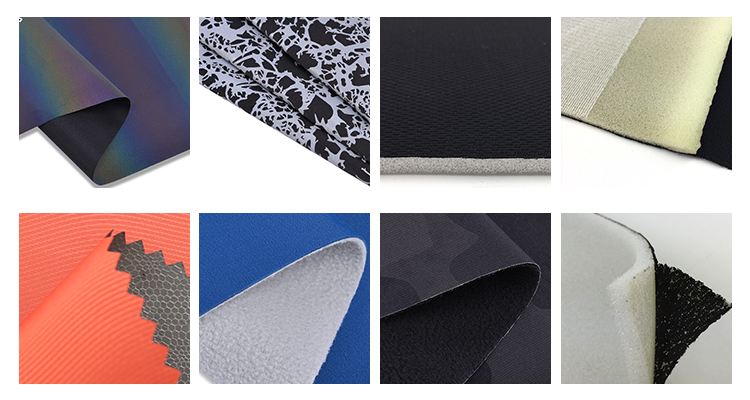

This machine uses solvent-free environmentally friendly PUR hot melt adhesive, which can be used for bonding cloth + cloth, cloth + film, sponge + leather, non-woven fabric and other composite materials required by the market. The composite product has the characteristics of environmental protection, good adhesion and flexibility, high and low temperature resistance, resistance to temperature after moisture reaction, good elasticity, wear resistance, oil resistance, anti-aging and other characteristics. In addition, PUR has excellent matte performance, low precipitation and neutral color characteristics, and can be applied to medical products that require repeated disinfection. The finished product compounded by the PUR hot melt adhesive compound machine has a lower loss rate and higher washing fastness. The PUR hot-melt adhesive laminating machine can replace traditional solvent-based laminating equipment. The production process does not use flammable, explosive and toxic solvent-based glue. The factory has no hidden dangers and meets the requirements of relevant departments; it can keep the front-line production workers away from solvents on the body. Hazards, the composite products have no solvent residues, meet the export environmental protection standards, and have great social benefits.

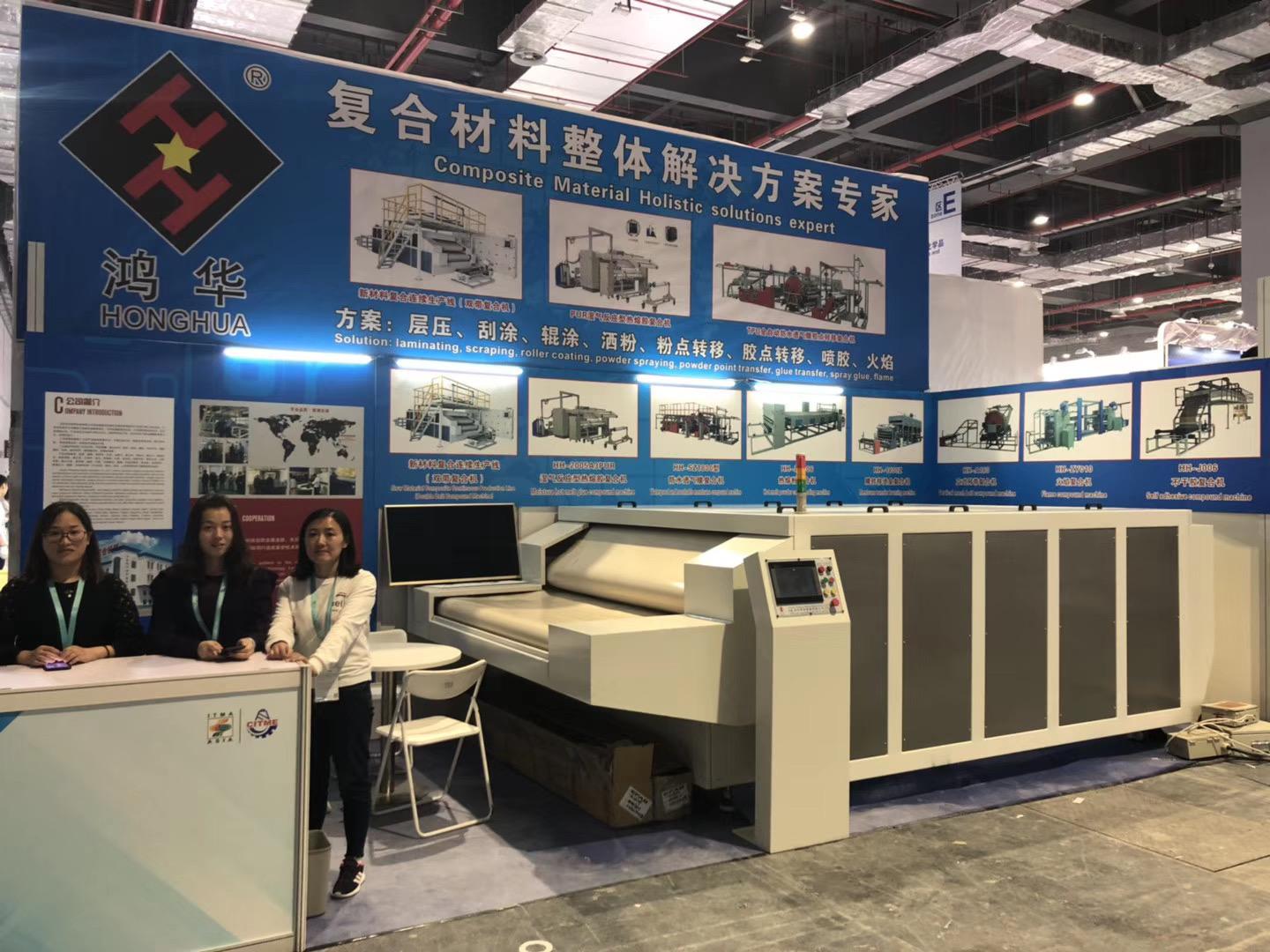

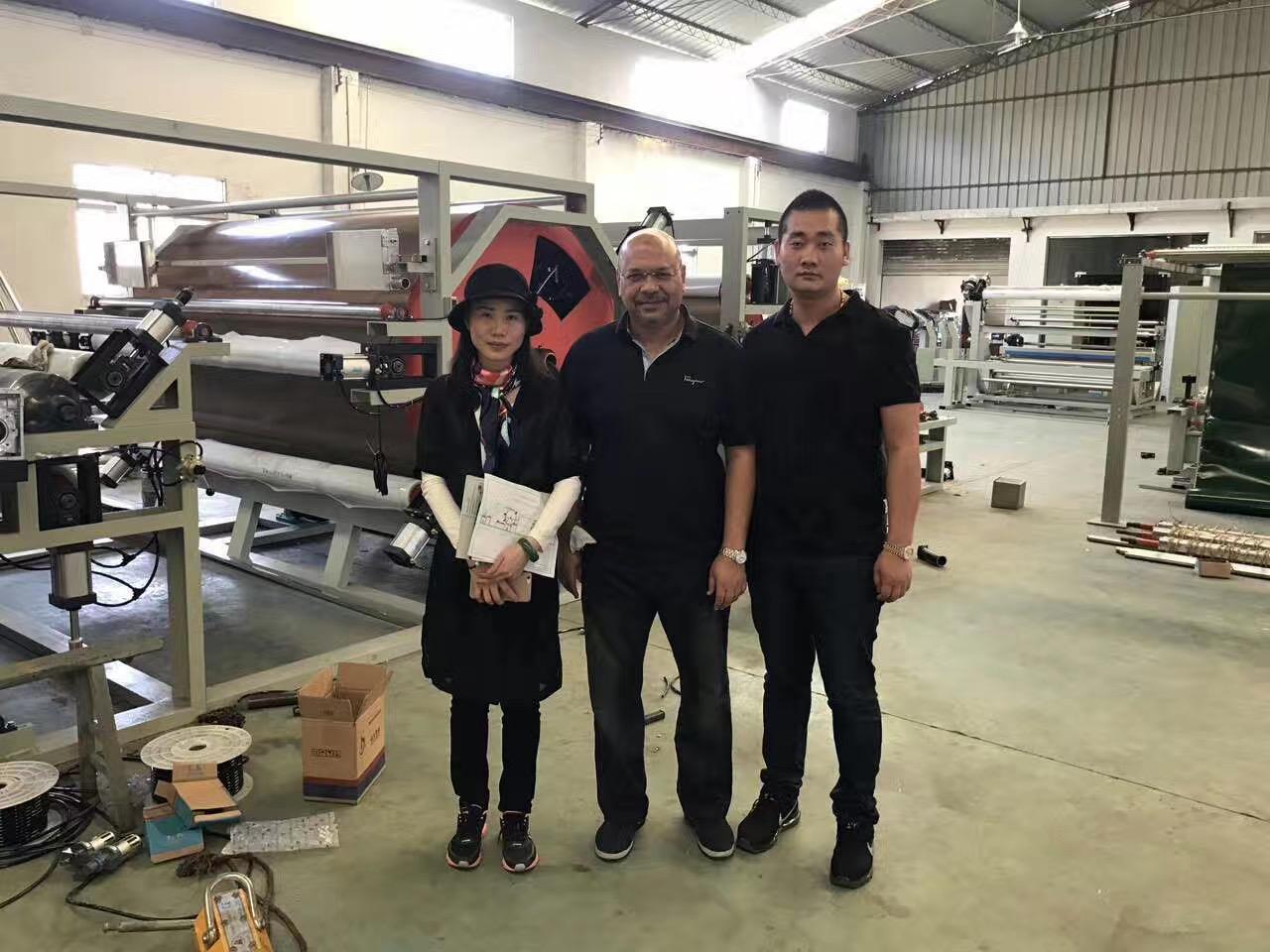

About Us

Honghua Special Equipment Co., LTD is a professional manufacturer and distributor of composite machinery and special equipment machinery. Company has our own power plant, has ten years of experience in this field.We can provide:Mesh belt type laminating machine, Flame laminating machine, Adhesive laminating machine, Hot melt adhesive laminating machine, Glue point transfer laminating machine, Laminating materials production lines, Continuous production line for UD without weft cloth, Wall cloth compound machine, Teflon belt laminating machine, Cutting machine, Cutting bed, etc.

Adhering to the development path of scientific and technological innovation, Honghua Machinery has established close technical trade relations with Russia, Turkey, Japan, France, Czech Republic, India, Vietnam and other countries. Our products are exported to more than 20 countries and regions. The company's product quality has been recognized by customers at home and abroad and enjoys a high reputation. All of our equipment can be customized.Welcome to our factory site investigation and cooperation!

Contact Us

Exhibition

Partner

Shipping Case

Certificate

The products of Jiangsu Honghua Special Equipment Co., Ltd. passed the ISO9001: 2000 quality system demonstration,

There are 40 products that have obtained patented products, and 12 products have passed the provincial new product scientific and technological achievements appraisal. The technical content of the products can replace imported products.

FAQ

1. Are you a trading company or a manufacturer?

We are a manufacturer with more than 30 years of manufacturing and R&D experience.

2. Where is your factory?

We are located in Dagang Metallurgical Industrial Park, Yandu District, Yancheng, just 1 hour from Shanghai High Speed Rail.

3. Does your company have a research and development department?

Yes, we have established Honghua R&D Center with Nantong University, Shanghai Tongji University, National Taiwan University. Honghua Machinery Co., Ltd. is a special equipment manufacturer with more than 30 years of experience in various laminating machines and UD laminating machines. We always believe in technology and market-oriented research. Every year, we develop a series of solutions for practical field application problems and develop new machines for customers, such as Tesla, Toyota, BMW, KIA, 3M, Volkswagen, Mercedes-Benz and other customers. We can also provide customized machine services according to the actual needs of customers.

Our goal is to solve every customer's on-site problem, achieve better material finishing/processing effect, and become a customer's think tank. If you have any new ideas about our machines, please feel free to contact us!

4. How can I trust your quality?

We have a strict and scientific quality control management system, and passed strict CE and ISO international certification to maximize product quality. We are committed to the research and development of new materials and new technology production lines. We have 100 new invention patents and 80 practical patents.

We have professional quality control personnel. For each step of our machine production, a group of quality control teams will be responsible for inspection. Before the item passes all inspections, the following steps can be performed.

At the end of the machine assembly, a series of tests will be performed. We will not deliver until the machine passes all tests.

We provide a one-year warranty for our machines. Usually, our customers have been using our machines for at least 10 years, 15 years or even 30 years. Throughout the life of the machine, parts will be replaced at cost.

5. How to operate the machine?

You have never used such a machine before. You just want to expand our business and start a new business. do not worry! When buying our first machine, almost most overseas customers were in the same situation. We have skilled and experienced follow-up service personnel who have developed complete solutions to meet the needs of customers like you. In addition, we have a team of professional engineers with rich experience in installation and commissioning, which can perform the installation, testing and operation guidance of overseas machines.

6. What is the transaction process?

Determine the plan, pay 30%-40% deposit, bring the test machine, if you are not satisfied with the sample test, we can refund the deposit. Pay the final payment and deliver.

Trading Area

Global