Overview

Product Details

360 degree rotating floor mounted 1ton 2ton 3ton 5ton 7ton 10ton 12ton 15ton 18ton 20ton pillar hoist jib crane for workshop

Slewing arm floor mounted jib craneSlewing arm floor mounted jib crane is mainly consisted of steel structure including pillar and slewing arm, electric hoist, slewing mechanism and electric parts.

The Jib Crane is widly used in assembly workshop, machining workshop, assembly mold, research laboratory, maintenance workshop, small freight station, warehouse, repair shops etc.

|

ITEM |

SPECIFICATION |

|

Capacity |

0.5t~20t |

|

Arm length |

1.2m~20m |

|

Lifting height |

1m~15m |

|

Rotate angle |

270° 360°degree |

|

Power source |

3-phase, 380v 50Hz or as required |

And the dimension and capacity all can be customized made as you need, even if you do not know the specific data clearly, pls tell us the problem you meet now and the objects you need to lift. Then our engineer team can suggest a best design and solution for you.

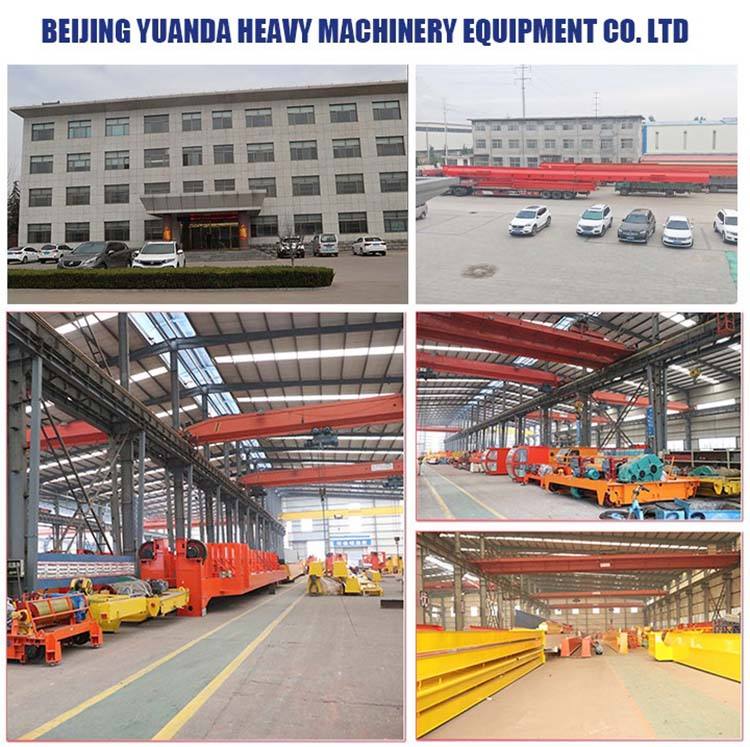

Beijing Yuanda Heavy Machinery Equipment Co. Ltd is a professional large-scale manufacture of all types of hoisting cranes and machinery equipments. Our company was established in 2009 located in Beijing which is capital of China. Our company has the professional technical teams to provide you the best solution if you want the customized products. We have always focused on research, development and innovation. Our watchword is "Providing the best product with the most competitive price; not only providing the professional pre-sale service but also providing the best after-sale service.We have over 20 years experience in R&D design. Our main products are gantry crane, jib crane, bridge crane, handing equipment, industrial manipulator, conveyors, industrial machineries and some other new products with modern technology.We look forward to your coming and hope our long good relationship.

Quality assurance — is a means of preventing defects and mistakes in manufactured products : At YUANDA, we are fully committed to providing quality products and services through strict quality control.1. Strict weld inspection process2. Strict size control for each parts3. Strict production processing and workmanship control ,QC inspection control 4. Strictly polished after the welding5. Before painting, cover and protect some parts ,ensure paint quality6. Before delivery ,pre-assembled & test whole crane ,ensure crane not dimension mistake and no quality problems