Overview

Product Details

Product Description

Hot Sell GSH-500L Stainless Steel High Pressure

Infrared Ray Heater Jacketed Reaction Kettle

PRODUCT DESCRIPTION

GSH-500L Stainless Steel High Pressure Infrared Ray Heater Jacketed Reaction Kettle is one of the reaction equipment normally used in chemical industry, etc. It is the equipment that mixes two kinds(or more kinds) of liquids and solids of certain volume and promotes their chemical reaction by using the mixer under certain temperature and pressure, and It is often accompanied by heating effect.

Application: Pilot reaction testing, Hydrogenation, Polymerization, Crystallization, Synthesis.

Product Paramenters

Volume | 500 Liters | |

Pressure | 0.2Mpa | |

Temperature | 350 ℃~450 ℃ | |

Material | SS304 /SS316/Q345R | |

Cooling type | Internal spiral coils | |

Sealing type | Machinery Sealing | |

Impeller type | Propeller, Turbine, Anchor type | |

Other materials, pressures & temperatures are customizable configuration. | ||

Product Features

1、At the same heating power, the heat efficiency of far infrared heating device is higher、warming faster、and no need thermal oil.(thermal oil should be exchange for every year ), but the initial investment in far infrared is slightly higher.

2、Another more important advantage is that the far infrared service life is much longer than the thermal oil of electric heating.

The above 2 heating methods are mainly aimed at the heating temperature of reaction kettle below 350 degrees, but the far infrared heating could reach over 450℃. This is the far-infrared heating device unique personality and characteristics.

Model No. | GSH-100 | GSH-200 | GSH-300 | GSH-500 | |||

Nominal Capacity (L) | 100 | 200 | 300 | 500 | |||

Design Pressure (bar) | -0.1-2Mpa customized | ||||||

Material | SS304 or SS316 Q345R wetted parts | ||||||

Design Temperature (℃) | 0~350 customized | ||||||

Stirring Speed (r/min) | 0-500 | 0-450 | 0-450 | 0-450 | |||

Motor Power (kW) | 2.2 | 2.2 | 4 | 5.5 | |||

Heating Method | Standard electric heating(Thermal oil, steam, far infrared heating available) | ||||||

Impeller type (Customizable) | Propeller, paddle, anchor, spiral, turbine, gas inducing type, etc | ||||||

Discharging type (Optional) | Discharging from bottom or above. | ||||||

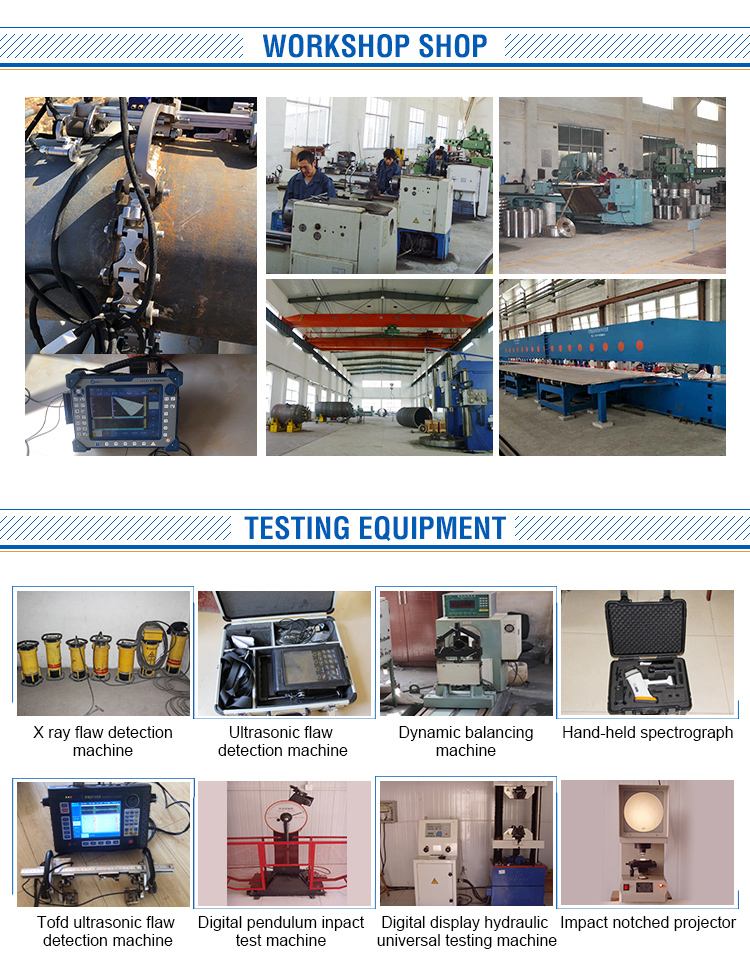

Fabrication process

Production Manufacturing

Magnetic Coupling

* 100% Sealing. no leakage. * Zero emission of hazardous fluids. * Suitable for pressure fluctuations. * Various capacities available. * Compact Design

Reducer

* Various explosion-proof grades, high efficiency and energy saving. * Variable frequency speed regulation can adapt to all kinds of rotating speed occasions. * Low noise and long service life.

Pressure Gauge

* The pointer display is intuitive and clear. * Convenient installation, suitable for a variety of complex environments.* Wide measuring range.

Agitator

* Different impeller type available for specific mixing mission.* Special impeller design according to process conditions.

Tubular Coil

* The velocity of medium is fast and the contact time is short *Large temperature difference of material medium* Beautiful appearance * It acts as a baffle

Serpentine Coil

* Long contact time of medium heat exchange * Large heat exchange area * It acts as a baffle

Pressure Vessel Barrel

* Can withstand a variety of temperatures, media * Various sizes and specifications

Upper Head

* Customized according to customer requirements * Set up safety monitoring devices, such as safety valve, bursting disc, etc

Fuel Port

* Add oil and lubrication to the bearing of magnetic drive system, increase the bearing life * The interface form can be connected with a variety of refueling equipment

Mechanical Seal

* It is suitable for low pressure and slight leakage * When the viscosity of material medium is high and the output torque is large * High torque output efficiency, low loss

Title goes here.

* High reaction efficiency * Full seal, zero leakage, reduce waste of leaking materials * Simple maintenance, energy saving and consumption reduction

Equipment Transportation

* Transport by special freight car * Naked transportation, convenient fixation

Company Profile

Weihai HuiXin Chemical Machinery Co ,. LTD

Weihai HuiXin Chemical Machinery Co ,. LTD was established in 2005. In the past 15 years, When our enterprise was first set up, its scale was smaller and its business was relatively simple. With our joint efforts, HUIXIN has a number of patent core technology, as well as dozens of excellent technical engineers. We have the most advanced production equipment and strict quality control system,A1,A2 design and manufacture of pressure vessels, ISO、CE certification, which ensure product quality absolutely perfect and the goods on time period.

Our manufactory locate at WEIHAI, SHANDONG Province, and occupies over 40 thousand square meters. There are 5 workshop, the usable area bonus is 20,000 square meters .The convenient transportation and ocean developed is a advantage to the other manufactures . We have the ability to manufacture and ship super heavy containers for overall delivery.

Related Products

Contact Us

Trading Area

Global