Overview

Product Details

With CE ISO Approved Hydraulic Press 400 650 Ton

We can provide total solutions, including machines, molds, product processing technology, automated production lines.

Technical Features

1. Using advanced hydraulic system, more steady, safer and more reliable.

2. Pressure, stroke and pressure keeping can be adjusted according to processing requirement.

3. Four columns are made of high-strength alloy steel with hard chrome plated surface and good abrasion resistance.

4. The moving bolster and worktable are equipped with optional ejecting cylinder, which meets different ejecting requirements of different products.

5. Digital control is achieved with PLC programming circuit design and touch panel operating system.

Machine Parts

Production Application

1. Hot extrusion molding stamping forging for auto parts, LED heat sink and hardware tools, etc.

2. Shallow stretching and molding for metal and nonmetal parts.

Machine Component

Why so many famous brand company cooperate with us ?1.Our factory have specialized in independent development and producing hydraulic press for 20 years.

So the product is stable and high quality.2. Machine body, we use bending structure , much stronger than the common welding structure .3. Oil pipe, we use Clip-on structure , much tight than common welding structure. Prevent oil leakage.4. We take integrated oil manifold block, much easier to check machine and repair machine. 5.The main components are imported from Germany, Italy and Japan . So the quality is near the Japan production, but the unit price is lower than Japan production.6.Our factory can offer full set line service, such as the mould,process technology, and other relative machines.

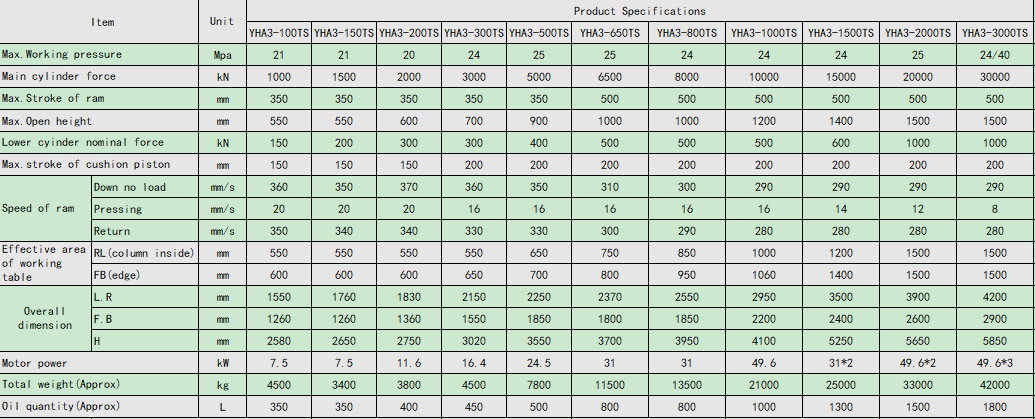

Standard Specification

All above specifications are standard sizes of hydraulic press machine.Special customized specification is also available for us!

Certificate

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Our Factory

Dongguan Yihui Hydraulic Machinery Co., Ltd. is a company specializing in all kinds of standard and

non-standard hydraulic press and stamping machinery’s design, manufacture, and sale.

YIHUI brand machines have been exported to over 40 pcs countries,such as Germany,USA,UK,Sweden, Japan,Slovenia,Togo, Malaysia,Vietnam,Pakistan and so on.

Especially speciallized in the servo system hydraulic press machine .

YIHUI hydraulic press machines are widely applied to hardware,automotive,die casting,electronic,cookware,paper and many other industries.

We are able to provide total solutions including machines,dies,product processing technology and automated production lines,etc.

Customer Show

Exhibition

Q1: Are you trade company or manufacturer?

Answer: We are an enterprise with sales, R&D, manufacturing and patent.Q2: Whether to provide quality assurance and complete after-sales support? Or say, does engineers available to service overseas?Answer: Yes!Warranty period of Our hydraulic press machine is 12 months, if necessary,we support the site installation,commissioning, technical guidance,and after-sales maintenance support.Q3:How can I know what kinds of the machine and which size suits my needs best?Answer: Before we have a deeper communication on the target machine, the drawings, material, pics, size and production of theproducts you are willing to make are necessary.Q4:Does customized is acceptable?Answer: Yes, we accept customized when necessary.Q5:Why choose us ?Answer: 1.Our factory has specialized in independent development and producing hydraulic press for 19 years. So the product isstable and with high quality.2. About machine body, we use bending structure which is much stronger than the common welding structure .3.About oil pipe, we use Clip-on structure which is tighter than common welding structure and can prevent oil from leakage.4. We take integrated oil manifold block which is much easier to check and repair machine.5.The main components are imported from Japan and Taiwan . So the quality of our machine is close to Japan while the unit price islower than Japan.6.Our factory can offer full set line service, such as the mould,process technology, and other relative machines.