Overview

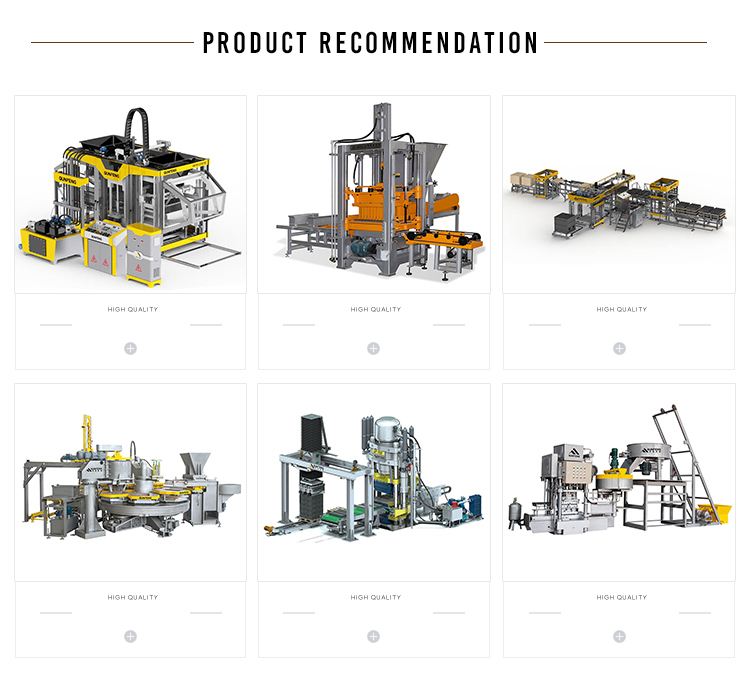

Product Details

Automatic Block Making Machine(QS1800)

This machine uses Electro-hydraulic integration technology which is more productive and more profitable than other ordinary block machine; The special vibration and feeding system of this machine can meet the needs of different blocks production for customers., block, grass-planting paver, curb stones, slope-protect bricks, inter-lock blocks and so on.

"Supersonic" series intelligent block machine is a high-efficiency model that is jointly developed by Qunfeng and German engineers. It is designed to match the various customer requirements, such as special-shape cement products, hollow bricks, paving bricks, curb stones and solid bricks, etc... and with features of easy operation, big capacity, high quality, high stability, low running costs and so on.

Features

1. Efficient servo vibration

Servo motor with forced synchronous mechanism is adopted to realize

A. output increasing:with fast dynamic response speed and short molding cycle, QS series block machines can have 8% larger production than machines with ordinary motor.

B. maintenance cost saving: with large load capacity, the servo motor is especially suitable for block production requiring instantaneous load fluctuation and quick start; being assembled with cooling system,the servo motor will not burn out at high temperature environment.

C. noise reduction: By changing the phase angle of the eccentric block, the residual vibration and noise can be quickly eliminated

2. Automatic mould lifting frame

The adjustment of the mold frame is realized by the automatic lifting frame and the auxiliary positioning of the screw rod, so that mould can be changed quickly and easily.

3. The material hopper door opening and closing are driven by a reducer, which is more stable and faster, improving the production efficiency.

4. German industrial appearance design:

Accord with high grade industry standard, so as to have excellent quality and high level of security.

5. Intelligent control:

The control system adopts Siemens PLC and other world-famous brands for sensor and electrical components, such as Germany Turk and French Schneider;

The operation is simple and easy;The control system has comprehensive fault alarm system and automatic diagnosis function, which can shorten the troubleshooting time by 30%.

6. Efficient hydraulic system

The hydraulic system adopts imported high dynamic proportional valve and high performance vane pump, which is characterized by convenient parameter adjustment, high pressure resistance, low noise, energy saving and easy maintenance.

Besides, it has the functions of pressure multi-point detection, oil temperature digital display, oil blockage alarm, etc.

7. Multi-purpose block machine

By changing moulds, one machine can produce various types of blocks and bricks, such as hollow blocks, paving bricks (with or without face color), solid bricks, curbstones and slope protection bricks.

8. Material feeding device:

To meet different block production requirements, there are a variety of material feeding carts for selection, such as 360° rotary feeding carts and quick swing shaft feeding carts.

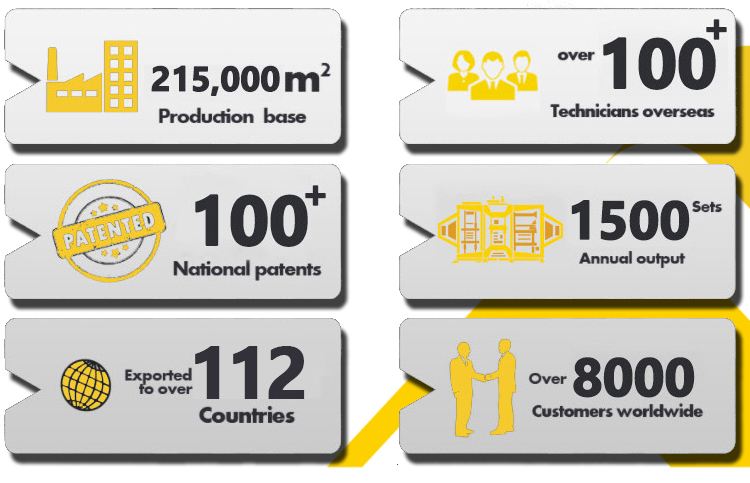

8 ADVANTAGES Expert in concrete block making machine industryIntellectualized control, 15% saving in labor cost . Electro-Hydraulic integrated technology , 20% raising in output; Suspension Type Vibration, 10% reduce in noise pollution; Fault Alarm System, 30% time saving in troubleshooting; Intellectualized Starting,20% improvement in working efficiency Material-Ratio program saved in PLC controller, no human disturbance. Intelligent remote control ,quickly solve the problem in all the places at any time. Customized design, efficient production that reduces costs.

Technical data

|

Technical data |

QS1800 |

|

Dimension(Main Machine) (mm) |

3980X3040X3610 |

|

Rating pressure (MPa) |

21 |

|

Vibration |

Table vibration |

|

suitable height for block( mm) |

50~200 |

|

Cycle time |

14~21sec |

|

Power ( kW ) |

103 |

|

Legend |

Product size (mm) |

Output |

QS2000 |

QS1800 |

QS1300 |

QS1000 |

|

|

200*100*60 |

Pcs./Hour |

9800 |

9400 |

9600 |

5700 |

|

|

225*112.5*60 |

Pcs./Hour |

8200 |

6850 |

6700 |

5100 |

|

|

400*150*200 |

Pcs./Hour |

5100 |

4050 |

3950 |

2700 |

|

|

400*200*200 |

Pcs./Hour |

3800 |

3400 |

3270 |

2250 |

|

Note: The moulding cycle time and the hourly capacity will be changed according to the proportion and the quality of the raw matirlal. |

||||||

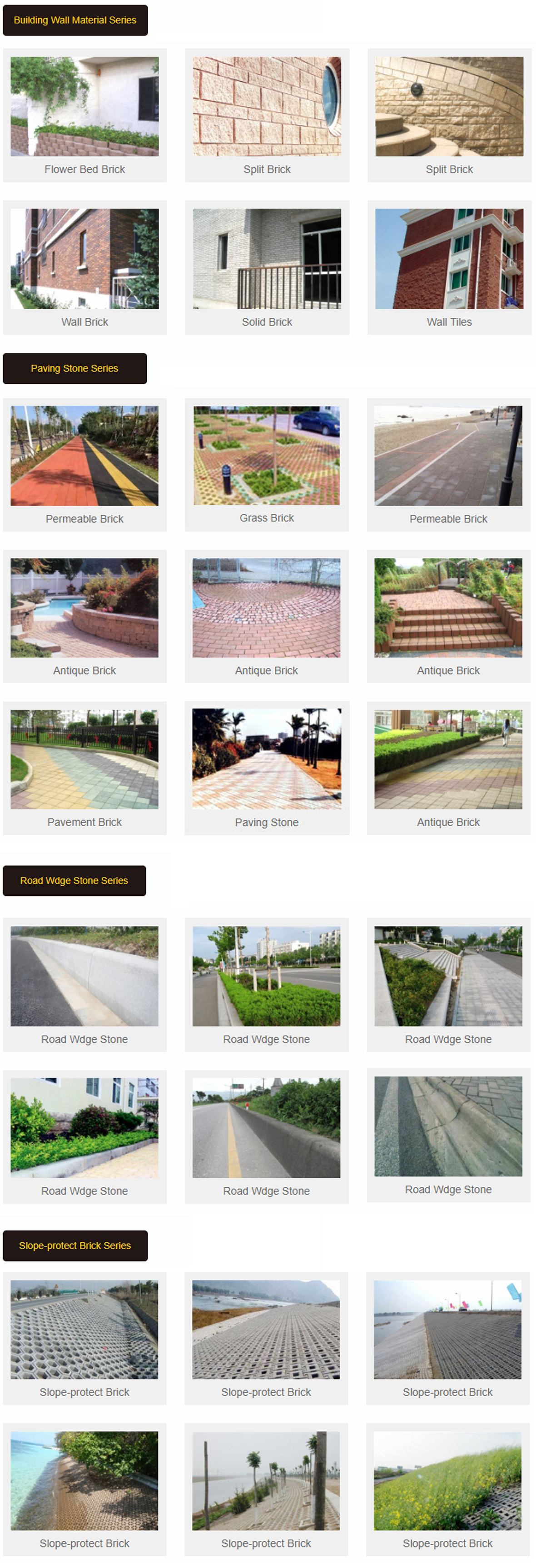

Product Application