Overview

Product Details

Product Description

FCH 1000 Standard type high pressure reactor vessel with propeller agitator

FCH 1000 Standard type high pressure reactor vessel with propeller agitator is specially used in industrial batch, continuous and long period reacting production. This series of reactors aims to finish specific mixing mission under certain pressure and temperature according to the customers requires. Permanent magnetic couplings driver can also be used in this series reactor, which will offer a reliable alternative to conventional dynamic seals due to their contactless and leakage-free torque transmission in agitators and mixers.FCH 1000 Standard type high pressure reactor vessel with propeller agitator can also set the following options:

*Magnetic and mechanical seal

*Various heating jacket: standard, half-pipe, limpet.

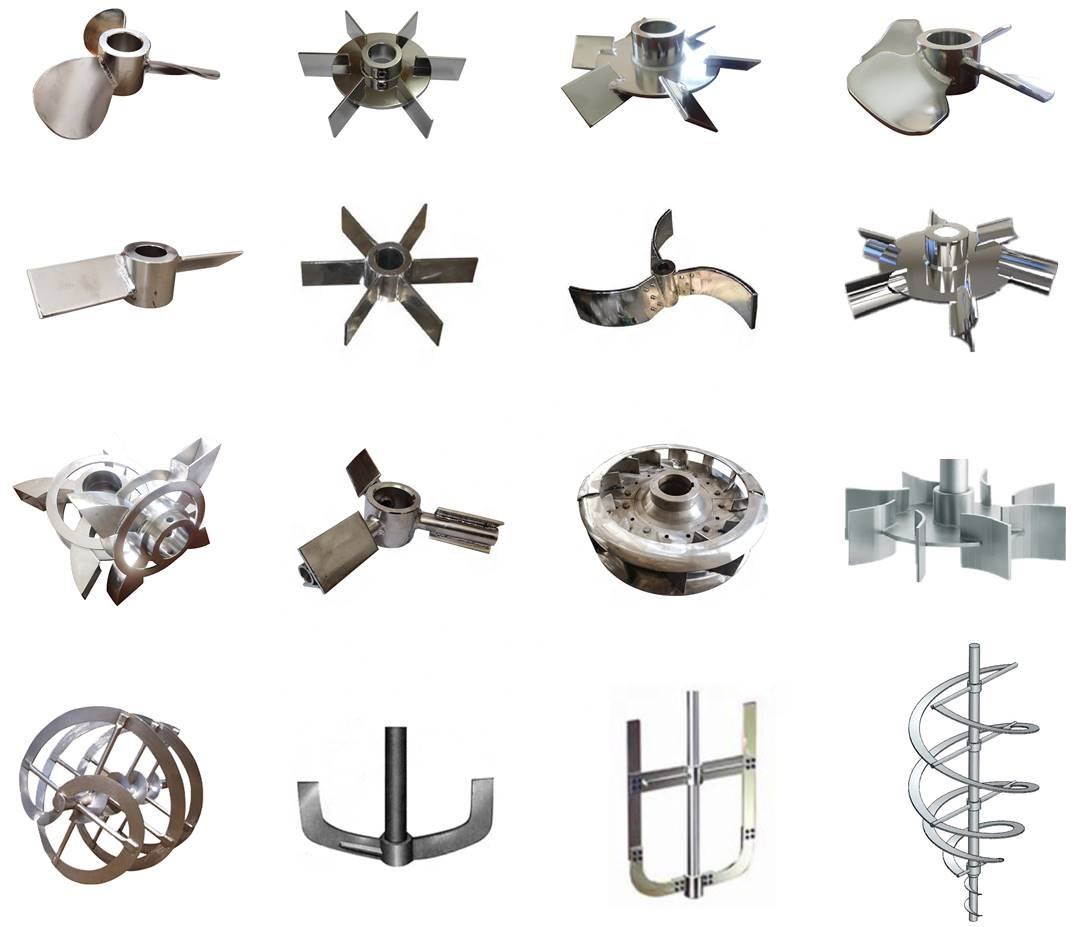

*Various impeller type available for mixing mission

*Various Anti-corrosion alloy material available

*Leg and lug support available

*Spiral, single layer or double layer tube condenser available

Applications: Petroleum, Chemical, Pharmaceutical, Pesticide, Food, Dye, Hydrometallurgy, etc.

Magnetic couplings application: Pressure Chemical Reactions – Reactions with noxious gases – potent pharmaceuticals – zero leakage requirements—Hydrogenation reactions.

Model | FCH 1000~80000 |

Norminal volume | 1000L-80000 L |

Material | CS, SS, other alloy lined |

Design pressure | -1~200 bar |

Design temp. | -196~350℃ |

Motor power | 5.5kW-125kW |

Stirring speed | 200~400rpm |

Sealing method | Magnetic or mechanical seal |

Stirrer | Propeller, turbine type, anchor type, ribbon type, others |

Heating type | Oil electric heatingOil heating Steam heating |

Product Features

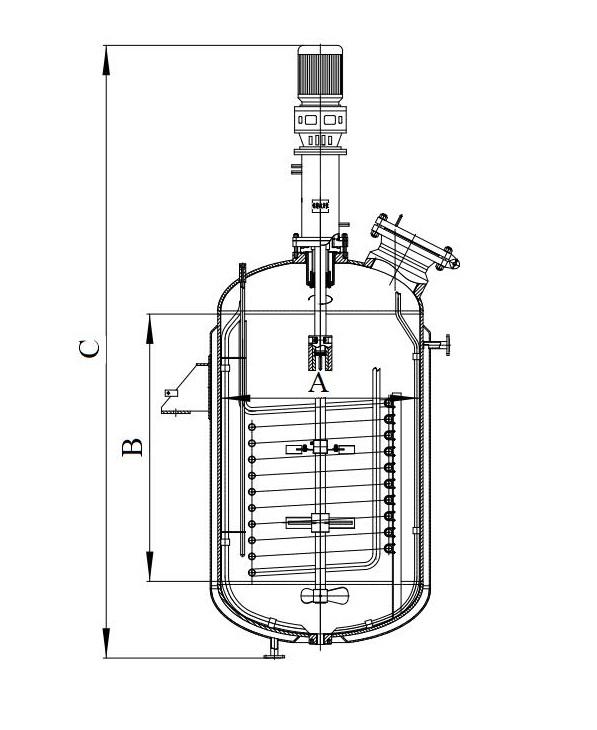

Internal Designing

Internal component design as per customer's requires, including:

*Internal condenser

*Agitator & impeller

*Dip tube

*Temperature measuring tube

*Various functional tube

*Cleaning device

*Bottom support & bearing

*Gas distributor

*Others

Customize for You

Reasonably customize the nozzle port and orientation, including:

*Manhole, liquid inlet, gas inlet, solid inlet, safety device, vent outlet... etc.

Magnetic Stirrer

* 100% Sealing. Zero leakage.

* Zero emission of hazardous fluids.* Suitable for pressure fluctuations.* Various capacities available.* Compact Design.

Agitator

*Different impeller type available for specific mixing mission.

*Special impeller design according to process condistions

Product Paramenters

Model No. | Vol. (L) | A (mm) | B (mm) | C (mm) | ||||

FCH1000 | 1000 | 1000 | 1100 | 3800 | ||||

FCH2000 | 2000 | 1200 | 1500 | 4200 | ||||

FCH3000 | 3000 | 1400 | 1700 | 4500 | ||||

FCH5000 | 5000 | 1600 | 2150 | 4700 | ||||

FCH6000 | 6000 | 1700 | 2350 | 5300 | ||||

FCH8000 | 8000 | 1900 | 2500 | 5700 | ||||

FCH10000 | 10000 | 2000 | 2800 | 5800 | ||||

FCH15000 | 15000 | 2400 | 2900 | 6100 | ||||

FCH20000 | 20000 | 2600 | 3300 | 7100 | ||||

FCH25000 | 25000 | 2800 | 3550 | 7600 | ||||

FCH30000 | 30000 | 2800 | 4350 | 9100 | ||||

Note: Larger size and specific data will be designed and confrimed according to your requires! | ||||||||

Details Images

Customization

Customized SpecificationsIf there has special process requires,HXHCEM will also customize for you!Pls list your basis process parameters like follows:1. Reactor volume2. Operating Temperature3. Operating Pressure4. Reactor Material / contacting components material5. Agitator type, and the Mixing Speed, motor power request?6. With heating device or not.7. Internal cooling coil or not, exchange area?8. Lifting device or not?9. Your other requests......Contact usWe like to help you to accomplish your plans.

Recommend Products

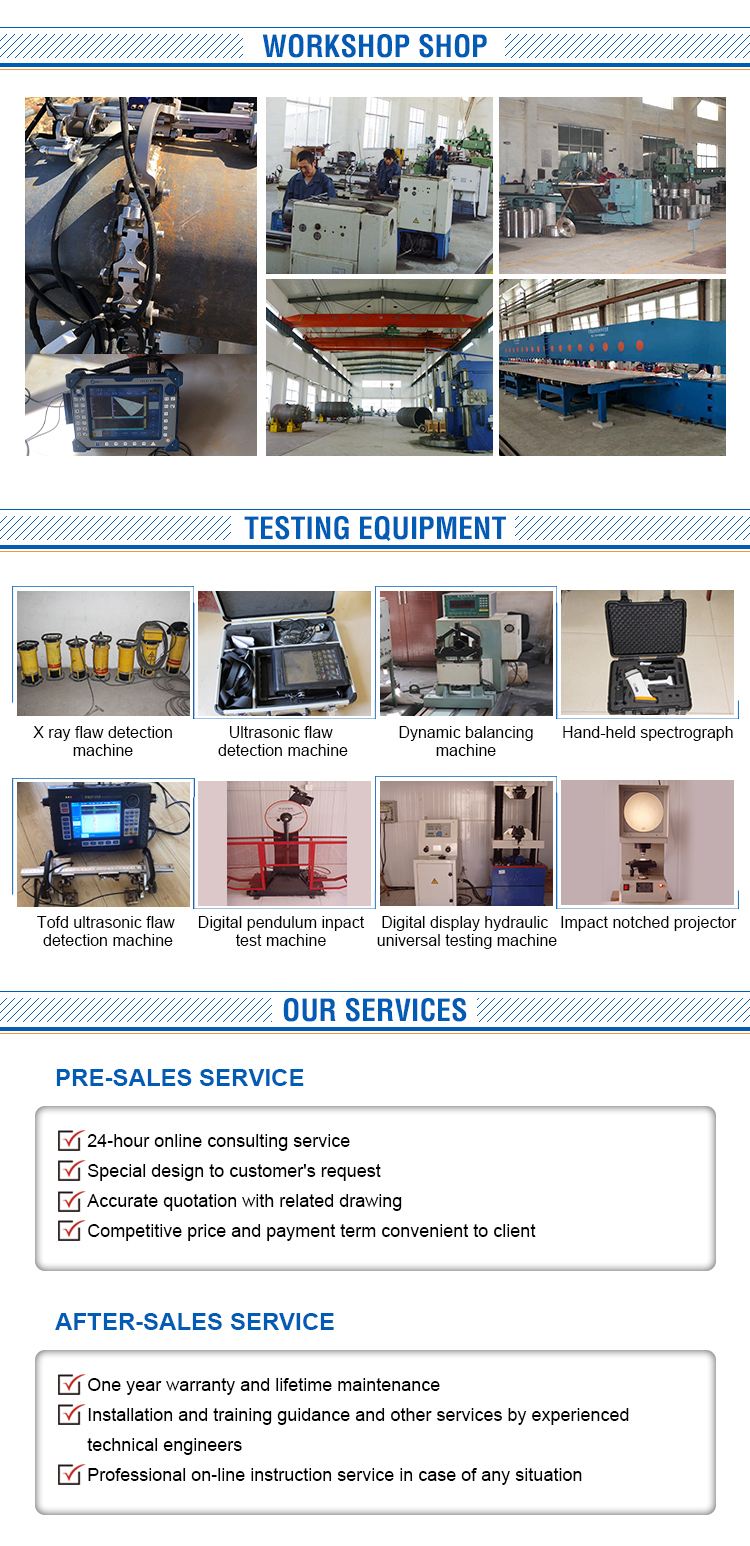

Workshop exhibition

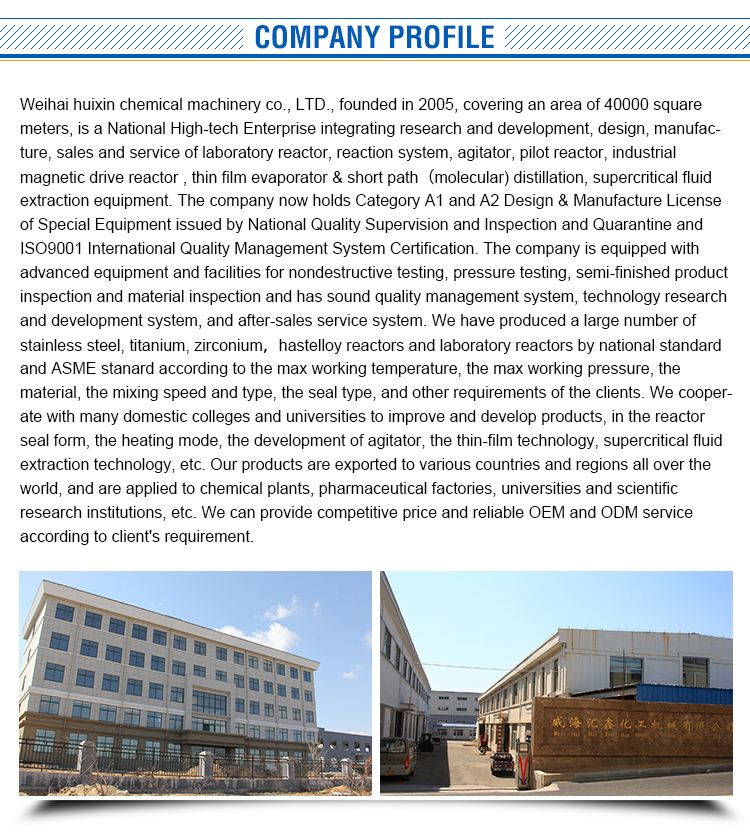

Company Introduction

Trading Area

Global