Overview

Product Details

Product Description

200 ton Servo Control Cold Forging Extrusion Press Machine Price Equipment

We can provide total solutions, including machines, molds, product processing technology, automated production lines.

Technical Features 1. Using advanced hydraulic system, more steady, safer and more reliable. 2. Pressure, stroke and pressure keeping can be adjusted according to processing requirement. 3. Four columns are made of high-strength alloy steel with hard chrome plated surface and good abrasion resistance. 4. The moving bolster and worktable are equipped with optional ejecting cylinder, which meets different ejecting requirements of different products. 5. Digital control is achieved with PLC programming circuit design and touch panel operating system.

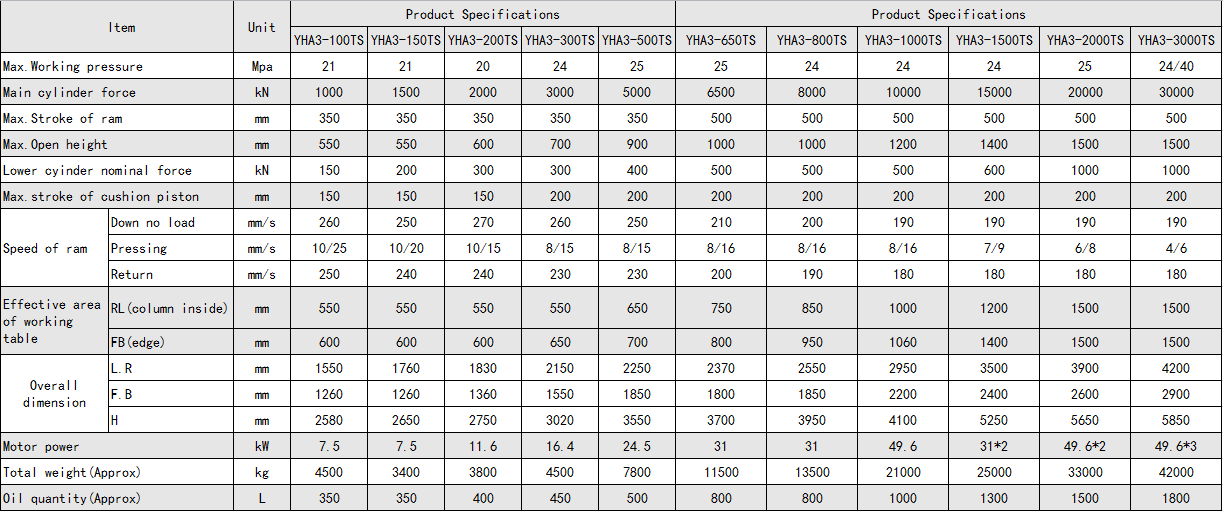

Standard Specification

We could customize for your special requiremet

Product Application

1)Cold forged molding and stamping for LED radiator, auto spare parts, cellphone casing and hardware tools, etc.

2) Molding and stamping for metallic and non-metallic.

Components Detail

View More

Response Rate 100%

Ce certificated metal forming flash remove trim hydraulic power press with big table

Company Introduction

Pre-Sales Service

* Inquiry and consulting support. * Sample testing support. * View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas.

Dongguan Yihui Hydraulic Machinery Co., Ltd, is experienced in designing and manufacturing various types of hydraulic pressmachines and stamping machines,especially specialized in manufacturing servo hydraulic press machine. The plant is established in1999 ,covers an area of 5,000 square meters. We are strictly implement the ISO9001 , CE, and SGS management standards. YIHUI brand presses have been exported to over 40 countries, such as Germany, USA, UK, Sweden, Japan, Slovenia, Saudi Arabia, ElSalvador, Togo, Malaysia, Singapore, Australia ,Vietnam, Pakistan, South Africa, and so on.Hydraulic press machine mainly appliedto hardware, automotive, die casting, electronic, cookware, paper and other industries.We can provide total solutions, including machines, molds, product processing technology, automated production lines.

Certifications

Our Advantages

1. Working table is made of No. 45 steel. It is processed with heating treatment and precision grinding, so it has good flatnessand good hardness, and there is no deformation.2. Columns are made of high-strength alloy steel. The column surface is hard chrome plated and processed with medium-frequencytreatment. It has very good oriented capability and abrasion resistance. 3. Piston is made of seamless steel. The surface of the piston is hard chrome plated and processed with medium-frequencytreatment. Therefore it possesses good hardness and high strength. And the speed is fast with mother-son type structure.4. Oil circuit is integrated manifold block type and it is easy for maintenance and repair. 5. Oil tube is clip-on type. Comparing with traditional welded type, there is no oil leakage.6. Main machine constitution is made of A3 (common carbon steel). The machine base is one-piece bending type, so it is strong andstable.

Customer&Exhibition

Packing&Shipping

Size | Accordingly |

Weight | Accordingly |

Packaging Details | The normal package is wooden case(Size: L*W*H). The wooden case will be fumigated if needed. If container is too tight, we willuse PE film for packing or pack it according to customers special request. |

Trading Area

Global