Overview

Product Details

Products Description

Mesh belt laminating machine alias: sponge laminating machine, water glue laminating machine, vertical mesh belt laminating machine, chenille carpet laminating machine, white glue laminating machine, water-based glue laminating machine, shoe material laminating machine, latex laminating machine Machine, sponge leather compound machine, etc.

Mesh belt compound machine use:

It is mainly suitable for coating and compounding between coil and coil, or coil and sheet. Such as lamb wool, polar fleece, plush, chicken skin fleece, sponge, cloth, EVA, human leather, sprayed silk cotton and other raw materials. It is widely used in gluing and laminating raw materials such as clothing, shoes, hats, bags, gloves, leather clothing, car interiors, toys, etc.

Roller: diameter (Φ1500-Φ2500mm) width (1800-3000mm) or customized |

Horsepower: 5HP+2HP single, linkage |

Electric heating power: (380V 50HZ) 1.5KW×24=36KW |

Heating wheel method: Teflon cloth or electroplating |

Gluing method: precision anilox roller gluing |

Mesh belt: high temperature resistant and breathable mesh belt/wool blanket belt |

Glue: white latex, acrylic glue, super glue, sponge glue |

Glue tank: water glue/oil glue/double glue tank |

Machine size (length*width*height): 7000×2400×2650(mm) or customized |

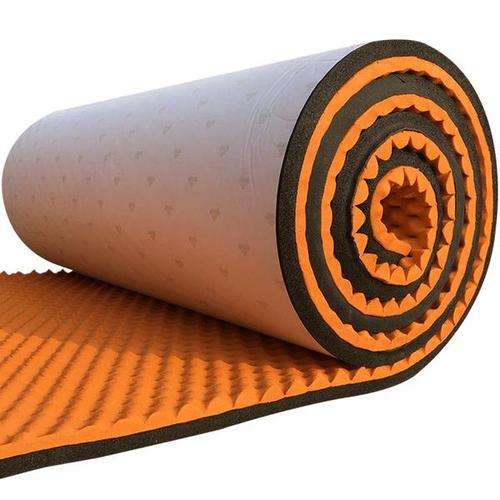

Applicable materials: sponge, pearl cotton, eva, leather, non-woven fabrics, carpets, floor mats, lighting |

Features

1. It uses water-based glue.

2. Improve the quality of the products greatly, save cost.

3. Vertical structure, low breakdown rate and long service time.

4. Equipped with high quality heat resistance net belt to make the laminated materials contact closely with the drying cylinder, to improve the drying effect, and make the laminated product soft, washable, and strengthen adhesive fastness.

5. This fabric to foam laminating machine has two sets of heating system, user can select one set heating mode or two sets, to reduce the energy consumption and lower costs.

6. Surface of heating roller is coated with Teflon in order to efficacious prevent the hot melt adhesive against sticking on the surface of roller and carbonization.

7. For clamp roller, both hand wheel adjustment and the pneumatic control are available.

8. Equipped with automatic infrared centering control unit, which can effectively prevent the net belt deviation, and ensure the net belt service life

9. Customized manufacturing is available.

10. Low maintenance cost and simple to maintain.

Configuration

Feeding device | 1 set |

Adhesive spreading decive | 1 set |

Laminating decive | 1 set |

Laminated manufacturing | 1 set |

Cooling system | 1 set |

Pulling device | 1 set |

Winding device | 1 set |

Feeding device | 1 set |

Process flow: blowing -- drying compound -- glue device -- inspecition -- meter meter -- wrap-up

Technical Parameters

power supply | 380V 50HZ three-phase / 220V 50HZ two-phase | |

Effective width | 1800mm Customized according to material width | |

roll width | 1800mm according to material width customized | |

heating drum specifications | Ø1200 * 1800mm | |

heating method of electric heating | ||

coating method | water-based glue | |

mechanical design speed | max 50m/min, normal 40m/min | |

machine power | 68kw | |

Dimensions (L * W * H): | Approx. 6800×2500×2700mm(L*W*H) | |

machine weight | about 3500kg | |

Applications

1. Gluing material and laminating with other materials, suitable for laminating cloth, sponge, nonwoven fabric, plastic, leather, synthetic leather, etc. 2. Widely used in cloth, shoe making, luggage, interior decoration, car interiors, toy and other industries.

Shipping

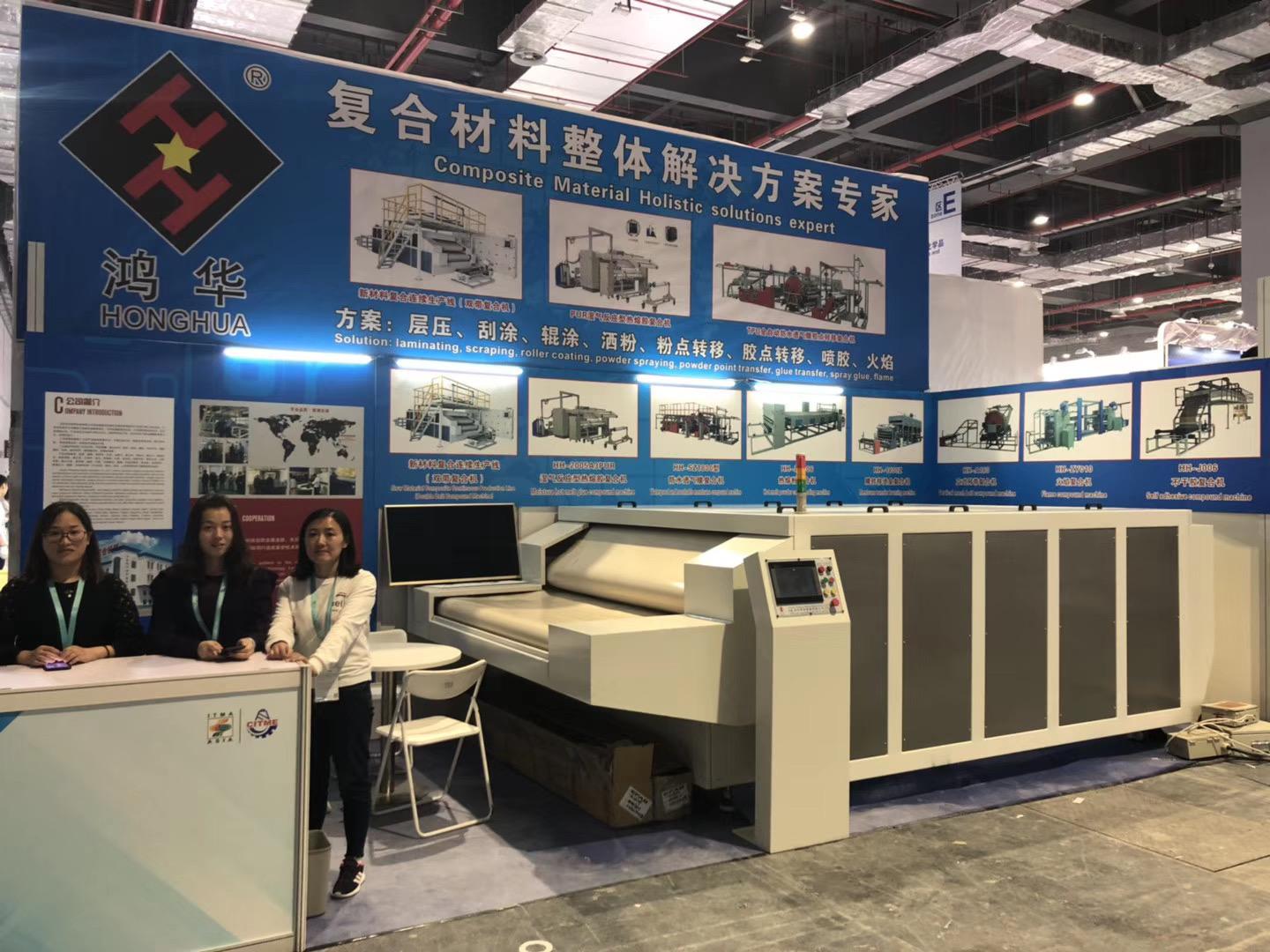

About Us

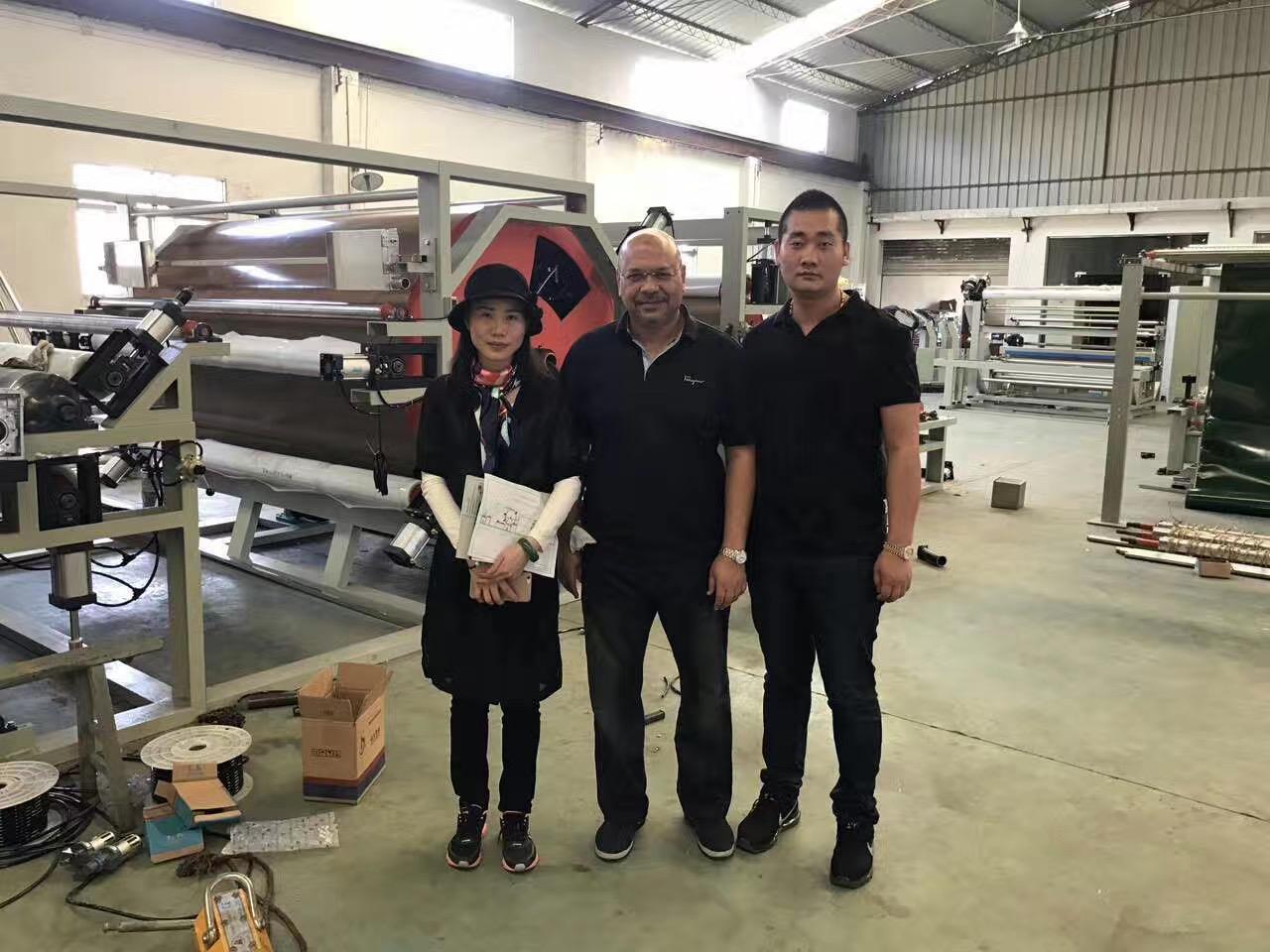

Honghua Special Equipment Co., LTD is a professional manufacturer and distributor of composite machinery and special equipment machinery. Company has our own power plant, has ten years of experience in this field.We can provide:Mesh belt type laminating machine, Flame laminating machine, Adhesive laminating machine, Hot melt adhesive laminating machine, Glue point transfer laminating machine, Laminating materials production lines, Continuous production line for UD without weft cloth, Wall cloth compound machine, Teflon belt laminating machine, Cutting machine, Cutting bed, etc.

Adhering to the development path of scientific and technological innovation, Honghua Machinery has established close technical trade relations with Russia, Turkey, Japan, France, Czech Republic, India, Vietnam and other countries. Our products are exported to more than 20 countries and regions. The company's product quality has been recognized by customers at home and abroad and enjoys a high reputation. All of our equipment can be customized.Welcome to our factory site investigation and cooperation!

Contact Us

Exhibition

Partner

Shipping Case

Certificate

The products of Jiangsu Honghua Special Equipment Co., Ltd. passed the ISO9001: 2000 quality system demonstration,

There are 40 products that have obtained patented products, and 12 products have passed the provincial new product scientific and technological achievements appraisal. The technical content of the products can replace imported products.

Trading Area

Global