Overview

Product Details

Products Description

The new high-tech flat composite machine is used in the new material industry-fiber reinforcement, aerospace, ballistics, filter materials, sound insulation materials, and honeycomb materials.

Applicable materials: prepreg, aerogel felt,carbon fiber, glass fiber, ceramic fiber felt, aramid, graphene, non-woven fabric, honeycomb panel.

The pressure is transferred through the upper and lower conveyor belts and the contact heating and cooling systems are integrated. The composite material will be uniformly heated. Due to the sufficiently long heating zone, the material will be perfectly composited and has high strength. The material can be heated after heating. The material is compounded together, and the height of the material is adjusted by the pressure roller. To ensure the composite strength, the material is cooled before going out of the conveyor belt. Through the gap between the conveyor belts and precise height adjustment, even the rigid plate of 150mmd can be compounded.

The new high-tech planar laminating machine is suitable for multi-layer laminating of thermoplastic materials, and the adhesive can be mesh or self-adhesive. The feature of this machine is that it does not deform when heated, keeps the material density unchanged, has a firm bond, and increases the production capacity by more than 12 times. Instead of manual gluing, the efficiency is increased by more than 15 times. Our company invested in a compound machine specially used for product testing. This machine will always be in stock. The specific customization plan still depends on the material characteristics and customer requirements. The overall production line can be increased or decreased (for example: winding device, unwinding device, automatic cutting machine)

The new material double belt flatbed laminating machine is mainly suitable for: Industrial textiles (covered textile composites) Automobile industry (PU-foam composite sensitive materials attached film) Composite materials (honeycomb multi-layer composite fibers) Filter material (Activated carbon filter device Non-woven material processing ) Medical (material compression film attached). The new material laminating machine mainly transfers the temperature and pressure through two upper and lower conveyor belts, and heat-compresses and combines two or more materials into one. The machine integrates the contact heating and cooling system. The composite material is uniformly heated and the material is cooled before it is pressed away from the upper and lower belts. Depending on the length of the heating zone, the material will be perfectly affixed with a good bond, with uniform gaps and precise spacing adjustments to ensure that the surface is flat and wrinkle free.

Technical Parameters

Overall dimensions: length 5800mm-width 3180mm-height 1800mm |

Length of heating zone: 1500mm; |

Length of cooling zone: 1200mm |

Composite material thickness: 0.1-100mm |

Maximum effective composite width: 500mm-3000mm |

Maximum temperature range of heating zone: 250℃ |

Adjustment range of upper and lower board gap: 0-150mm |

Optional thickness of PTFE belt: 0.35-0.6mm |

Belt conveying speed: 1-30m/min |

Adjustable range of pressure roller gap: 0-150mm |

Adjustable range of pressure roller pressure: 0-7Mpa |

PLC touch screen control panel |

Total power: 90 KW |

Configuration

Configuring single

1. Compound device: upper and lower conveyor belt, heating device, cooling device, conveyor belt gap adjustment device, pressure roller constant pressure device.

2. Conveying flat belt: anti-static Teflon belt, the periphery of the flat belt is pulled by a tension spring, the power is driven by the chain, and the flat belt is driven by the motor through the active and passive rubber rollers and the chain.

3. Heating device: The upper and lower special heating plates are distributed and heated, and the Teflon flat belt is evenly heated to ensure the balance of the left and right temperature differences. The upper and lower heating plates are independently controlled and displayed by nine sets of temperature controllers. Ensure the heating temperature.

4. Cooling device: The upper and lower cooling aluminum plates are symmetrically distributed, and the flat belt is uniformly cooled. The cooling water is circulated through the cooling unit through the cooling unit to ensure the cooling temperature. Ensure even cooling and no deformation.

5. Flat belt gap adjustment device: The elevator on both sides is controlled by the motor, the encoder measures and feedbacks, and the gap is controlled by the program.

6. Pressure roller gap adjustment device: the encoder performs measurement and feedback, and the gap is controlled by the program.

7. Pressure roller constant pressure device: The pneumatic pressure of the upper and lower rollers can be adjusted through the air cylinder, pressure sensor and regulating valve, and the pressure can be adjusted on the touch screen.

Features

1. The flat-bed conveying design can convey soft coils or hard plates. From soft foaming materials and textiles to hard carbon steel plates can be processed by this system.

2. The temperature zone thermal control is distributed in the upper end, lower end, middle section and edge area of the conveying channel. The temperature of each temperature zone can be set independently, which provides a perfect solution for different heating temperatures on both sides of the material.

3. Both roll and sheet can be processed, and the combination of sheet + roll + sheet can also be processed.

4. The conveying system does not produce tension on the material during the whole process, and provides an ideal conveying method for unidirectional materials (non-weft cloth), jacquard fabrics, very soft non-woven fabrics and other loose structure products.

5. Pressure can act on the material during the heating and cooling process, and the material can be accurately compressed to a specific thickness and shaped as needed.

6. Multi-layer materials can be completed in one step.

7. It can be fed from light and thin materials of a few microns to thick materials of 150mm thickness.

8. The roller pressure system can provide additional pressure, and a single set of cargo can be designed with multiple pressure systems as required.

9. The working speed of the equipment can be selected according to the characteristics of the material.

10. The upper and lower conveying devices can output zero pressure when conveying materials, and can output strong pressure.

11. The composite equipment can be integrated into a large number of auxiliary equipment to form a complete production line, and can also be used as an independent equipment.

Applications

Double belt lamination compound machine widely used as a flat type heating composite device in which a viscous resin-attached fabric or non-woven fabric is controlled to have its own adhesion by controlling temperature, speed, and pressure. Can be used to achieve continuous work, but also small batch test production.

Shipping

About Us

Honghua Special Equipment Co., LTD is a professional manufacturer and distributor of composite machinery and special equipment machinery. Company has our own power plant, has ten years of experience in this field.We can provide:Mesh belt type laminating machine, Flame laminating machine, Adhesive laminating machine, Hot melt adhesive laminating machine, Glue point transfer laminating machine, Laminating materials production lines, Continuous production line for UD without weft cloth, Wall cloth compound machine, PTFE belt laminating machine, Cutting machine, Cutting bed, etc.

Adhering to the development path of scientific and technological innovation, Honghua Machinery has established close technical trade relations with Russia, Turkey, Japan, France, Czech Republic, India, Vietnam and other countries. Our products are exported to more than 20 countries and regions. The company's product quality has been recognized by customers at home and abroad and enjoys a high reputation. All of our equipment can be customized.Welcome to our factory site investigation and cooperation!

Contact Us

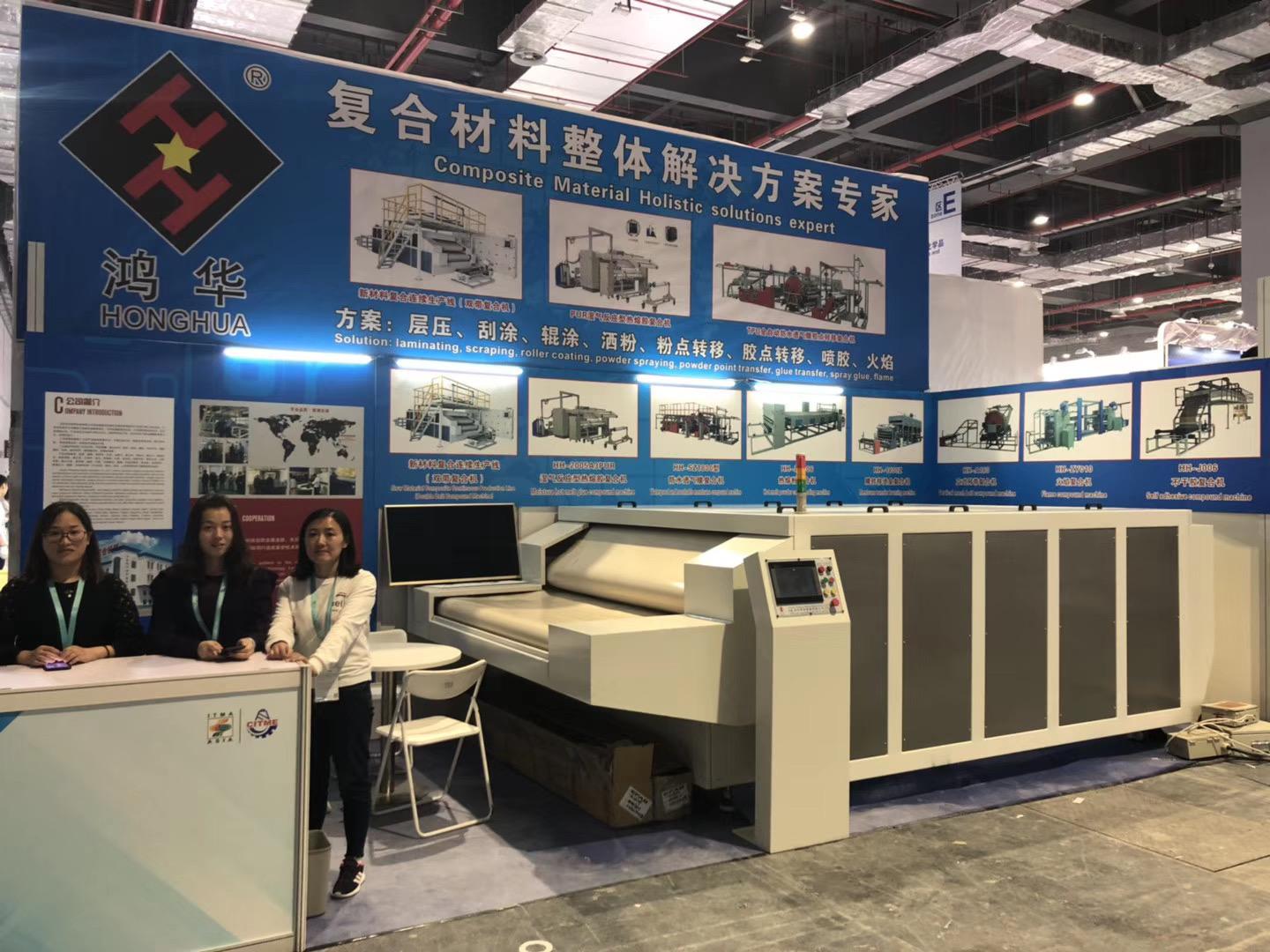

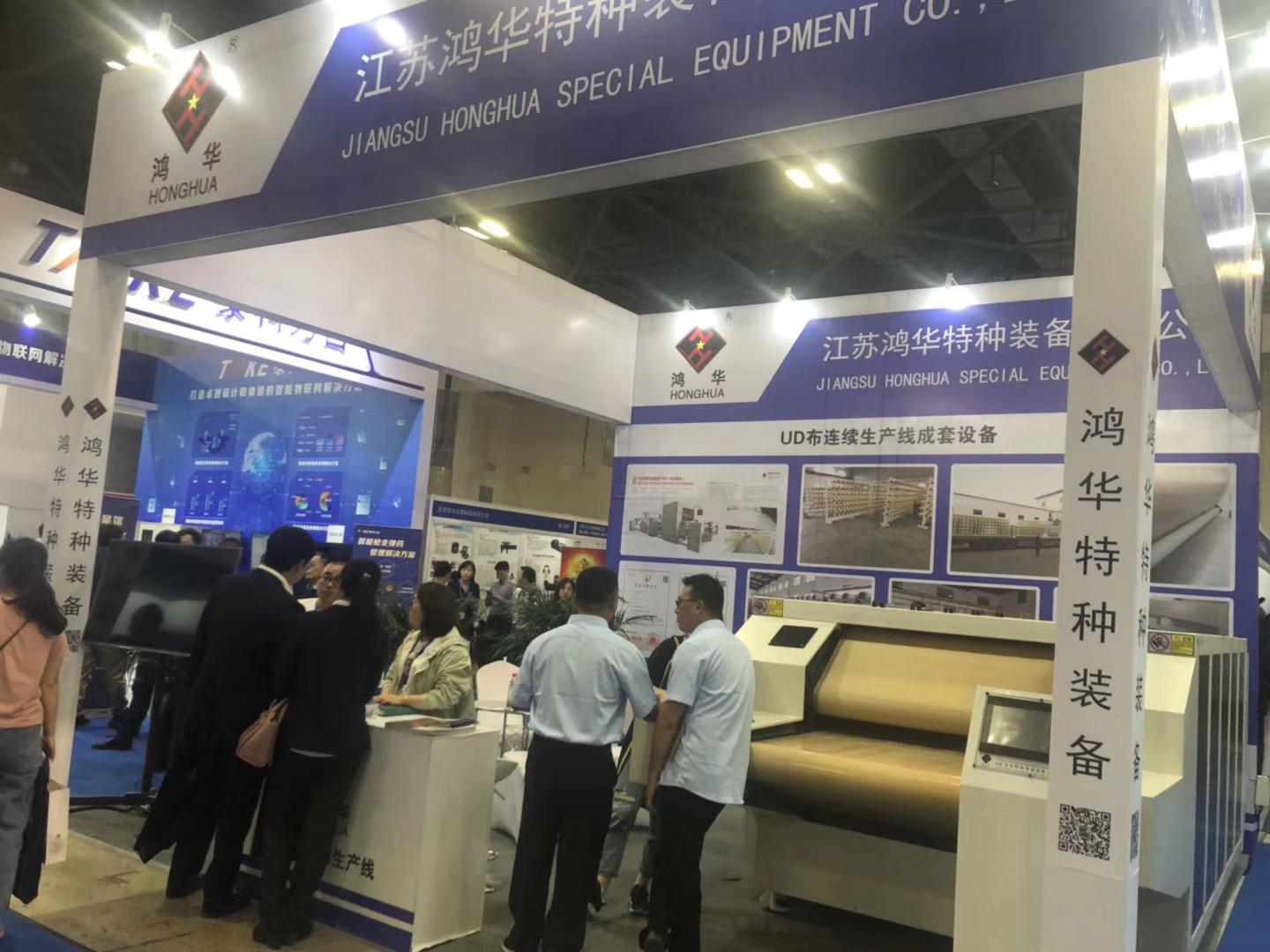

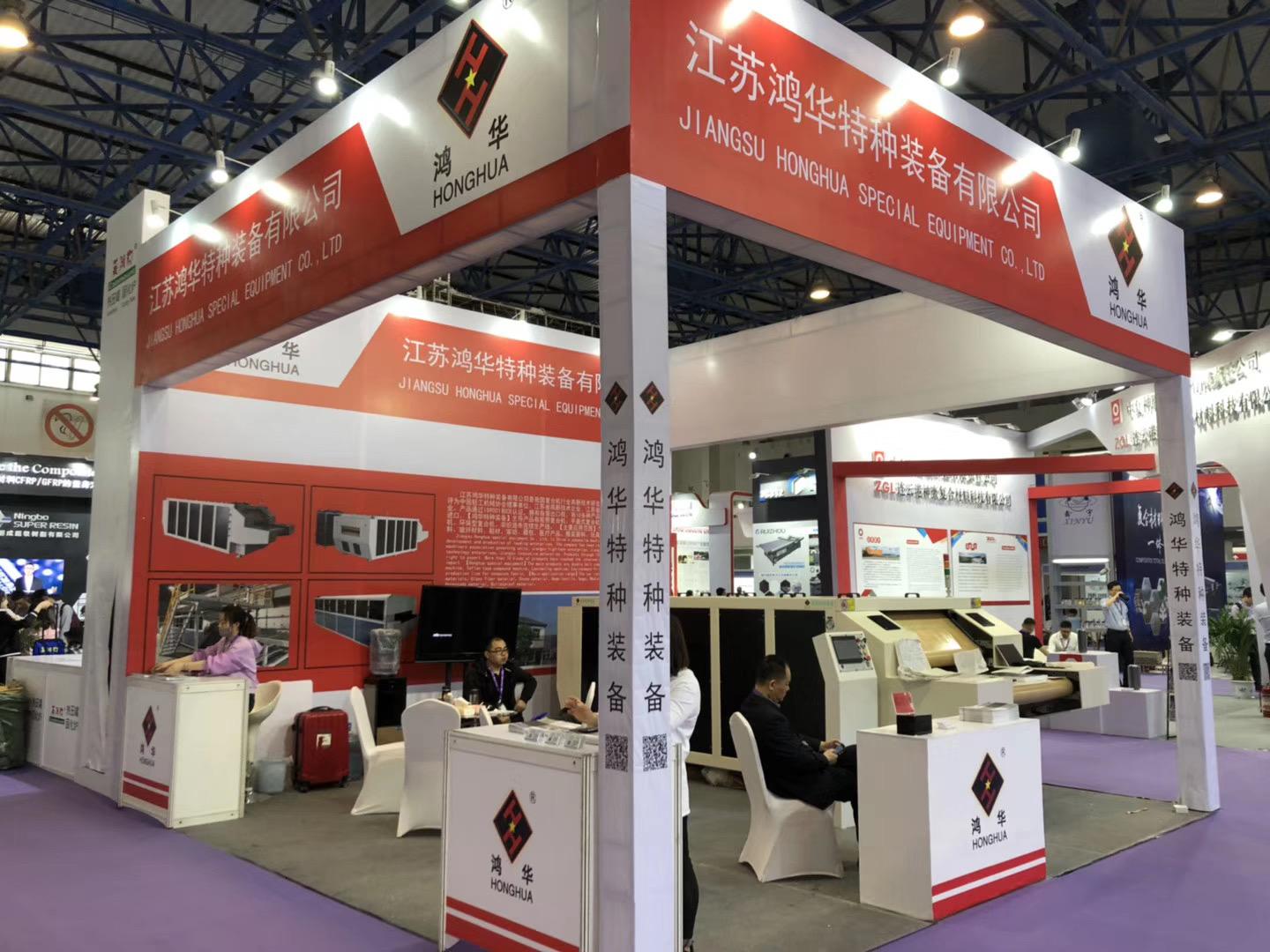

Exhibition

Partner

Shipping Case

Certificate

The products of Jiangsu Honghua Special Equipment Co., Ltd. passed the ISO9001: 2000 quality system demonstration,

There are 40 products that have obtained patented products, and 12 products have passed the provincial new product scientific and technological achievements appraisal. The technical content of the products can replace imported products.

Trading Area

Global