Overview

Product Details

Product Overview

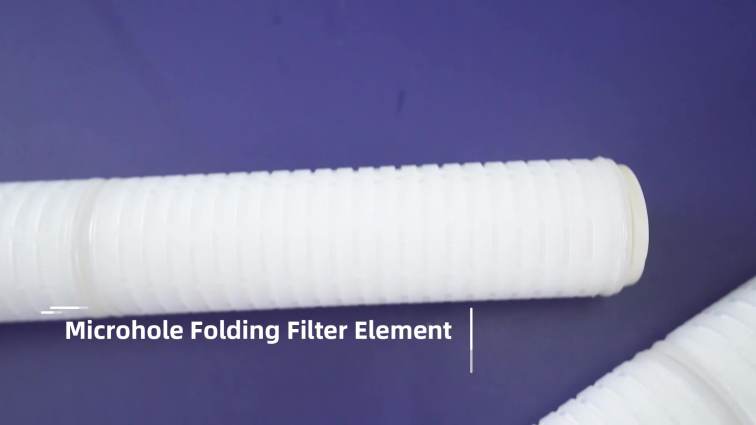

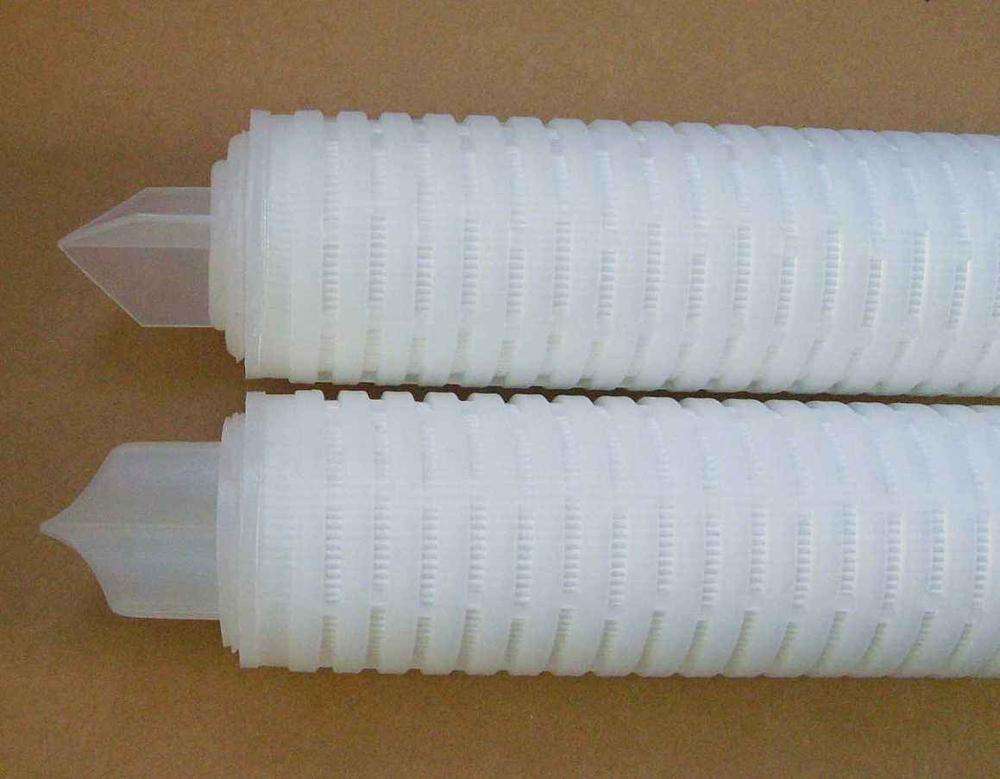

PES Pleated Liquid Filter Cartridge For Water Treatment

Microporous membrane filter and cartridge are the currently popular microporous filtration equipment in the world: it uses a composite folding microporous membrane as filtration medium, by means of the membrane surface microporous screening to filer a certain particle, it has some advantages, such as, high filtration efficiency, the filtrate Good quality, small the filter size, large flow, easy operation, low production costs.

PP(polypropylene)

The filter holds a folding, large membrane filtration area, large dirty holding capacityLow pressure drop, long service lifeOverall filter made of 100% pure PP material, with a wide range of chemical compatibilityOptional for a wide filter accuracy

PES( polyether sulfone)

It has a good high temperature, acid and alkali resistanceFiltration Membrane has a good hydrophilicity and large fluxWithout media shedding, in line with medicine, food industry requirements

NYLON

Nylon grease is hydrophilic, without pre-wettingPore diameter size homogeneous distribution, good filtration effectHigh strength, good chemical compatibility, wide applicabilityWithout fiber shedding, in line with the pharmaceutical industry requirements

PVDF(Polyvinylidene Fluoride)

The filter is hydrophobic and ensures absolute sterilization under wet or dry conditions. 100% of phage is filtered in gas.

Resistant to high temperature and can be repeatedly on-line high-pressure steam disinfected, high strength, impact resistance

Resistant to oxidation, can be used for ozone disinfection

PTFE( polytetrafluoroethylene)

The membrane has strong hydrophobicity, can ensure absolute sterilization in wet or dry conditions, 100% removing phage in the gas.

Resisting high temperature, impact and corrosionThe low initial pressure difference, large gas flux and long service life

Product Paramenters

Filter Media Option | PP | PES | Nylon 6/66 | PVDF | PTFE | ||||

Length | 2.5'', 5, 10, 20, 30, 40 inch | 2.5'', 5, 10, 20, 30, 40 inch | 2.5'', 5, 10, 20, 30, 40 inch | 2.5'', 5, 10, 20, 30, 40 inch | 2.5'', 5, 10, 20, 30, 40 inch | ||||

Micron Rate | 0.1, 0.2, 0.45, 0.65, 0.8, 1, 2, 3, 5, 10, 20, 25, 30, 50, 60 micron | 0.1, 0.2, 0.45, 0.65 micron | 0.2, 0.45, 0.65, 1 micron | 0.2, 0.45 micron | 0.2, 0.45 micron | ||||

End Cap | DOE, 222+Fin, 222+Flat, 226+Fin, 226+Flat | DOE, 222+Fin, 222+Flat, 226+Fin, 226+Flat | DOE, 222+Fin, 222+Flat, 226+Fin, 226+Flat | DOE, 222+Fin, 222+Flat, 226+Fin, 226+Flat | DOE, 222+Fin, 222+Flat, 226+Fin, 226+Flat | ||||

Inner Diameter | 28mm | 28mm | 28mm | 28mm | 28mm | ||||

Outer Diameter | 69mm (can be customized) | 69mm (can be customized) | 69mm (can be customized) | 69mm (can be customized) | 69mm (can be customized) | ||||

Gasket/O ring material | Silicon/EPDM/NBR/Viton/Teflon | Silicon/EPDM/NBR/Viton/Teflon | Silicon/EPDM/NBR/Viton/Teflon | Silicon/EPDM/NBR/Viton/Teflon | Silicon/EPDM/NBR/Viton/Teflon | ||||

Effective filtration area | 0.4-0.7m² | ≥0.6m² | ≥0.6m² | ≥0.72m² | ≥0.72m² | ||||

Max.working pressure difference | 0.42Mpa at 25ºC | 0.42Mpa at 25ºC | 0.42Mpa at 25ºC | 0.42Mpa at 25ºC | 0.42Mpa at 25ºC | ||||

Max.back pressure | 0.28Mpa at 60ºC | 0.21Mpa at 25ºC | 0.35Mpa at 25ºC | 0.21Mpa at 25ºC | 0.35Mpa at 60ºC | ||||

Max. working temperature | 88ºC at 0.28Mpa, 60ºC at 0.42Mpa | 140ºC at 0.28Mpa | 49ºC at 0.21Mpa | 80ºC at 0.173Mpa | 142ºC at 0.276Mpa | ||||

Sterilizing temperature | 121℃, 30mins | 121℃, 30mins | 121℃, 30mins | 121℃, 30mins | 121℃, 30mins | ||||

Product packaging

Certifications

Company Profile

Xinxiang North Filter Co., Ltd.

Xinxiang North Filter Co., Ltd. is a high-tech enterprise specializing in developing andmanufacturing various filters and purification equipments over 20 years. Our leading products are divided into four series, air filters, water filters, oil filters, water-oil separationdevices, etc. Our company has many kinds of advanced production and testing equipments, HEPA filter production lines and a500-square-meter cleaning room for thousands of grade filtration.

Trading Area

Global