Overview

Product Details

Products Description

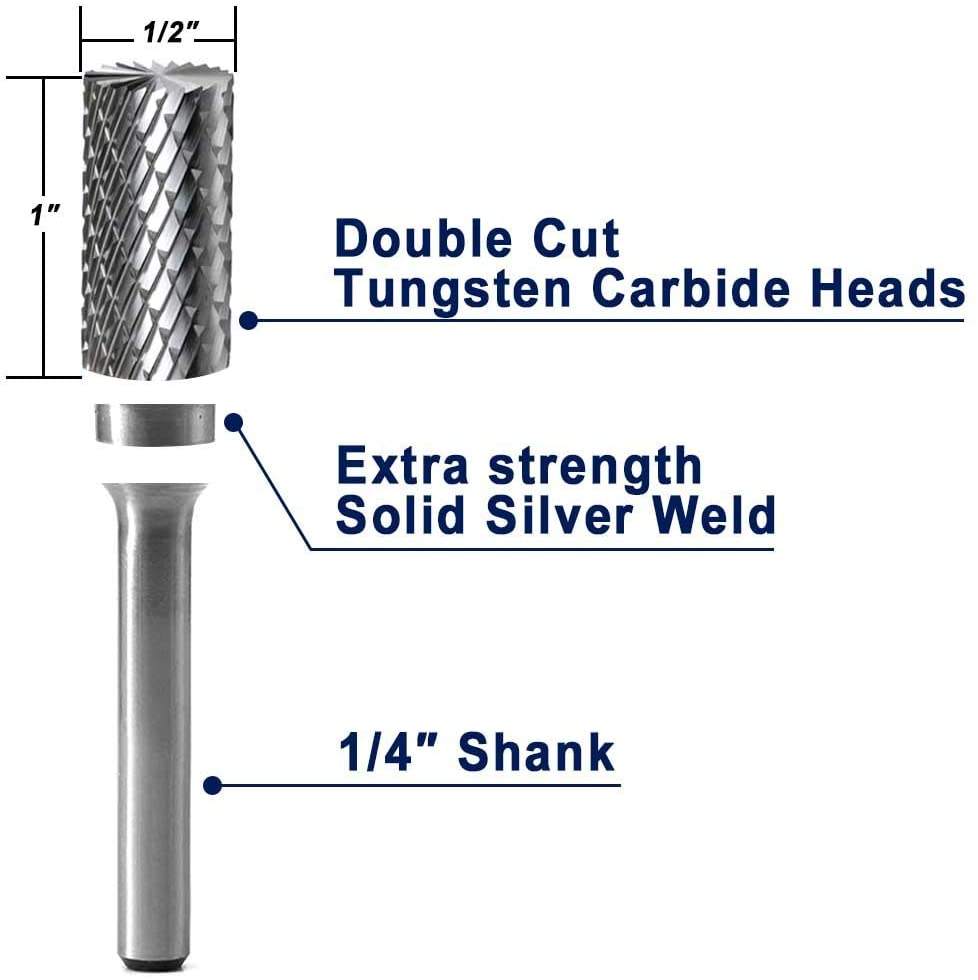

Characteristics of silver welding

Top manufacturing process

silver Welding is currently the world's most advanced welding process ,and the burrs will best stronger,better in quality and safer.The processing temperature is low,so it can avoid high temperature damage to tungsten carbide alloy

Cutter Pattern | * DX: Double Cut Tungsten Carbide Burr* C: Coarse Cut Tungsten Carbide Burr * M: Standard Single Cut Tungsten Carbide Burr* W: Aluminum Cut Single Cut Tungsten Carbide Burr* F: Fine Single Cut Tungsten Carbide Burr* Z: Cast Single Cut Tungsten Carbide Burr* MX: Standard Cross Gear Cut Tungsten Carbide Burr* ZX: Casting Cross Cut Tungsten Carbide Burr* L: Diamond Cut Tungsten Carbide Burr* SX: Steel File Cross Cut Tungsten Carbide Burr* FX: Fine Tooth Cross Cut Tungsten Carbide Burr* CX: Coarse Cross Cut Tungsten Carbide Burr* WX: Aluminum Cut Cross Cut Tungsten Carbide Burr | ||||||

Features | * Used to process all kinds of metal (including hardened steel) and nonmetal* High production efficiency, Can reduce labor intensity convenient to use.* Widely used in the pneumatic or electric tools. | ||||||

Specification | * HRA: ≥ 85* Suggested RPM:25000-50000, Max RPM 70000* Package:Individually packaged and can be customized* Technology:100% Flat bottom silver welding tungsten carbide burrs | ||||||

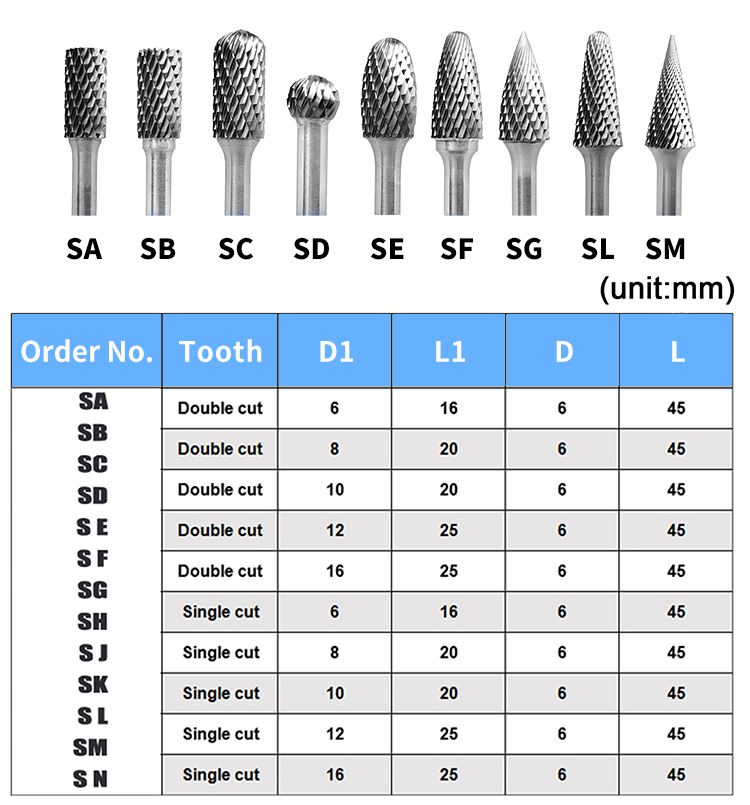

Product Paramenters

Product Show

Application scenarios

Main Products

Trading Area

Global