Overview

Product Details

Product Overview

automatic clay brick making machine prices for malawi

This type of brick making machine is developed by combining the advantages of several other manual brick making machines. The machine adopts spring buffer to reduce wear and increase mold pressure, thereby increasing block forming speed, increasing block density and reducing raw material consumption. It requires workshop AERA 30-50CBM and land AERA 200-400CBM. It only requires 2-3 workers to produce, and the investment is low, so this manual hollow block machine is very suitable for factories or family businesses.

working principle of

automatic clay brick making machine prices for malawi

This brick machine is based on the technical transformation of the original block forming machine. The original primary vibration is changed to the secondary vibration of the mold core, which makes the block density higher, the molding speed faster, and the block strength is more uniform. It is suitable for Any customer who has a block making machine. Existing cement workplaces and pallets consumed can be reduced

Dimensions | 1500*1335*1580 mm |

Molding cycle | 45s |

Main form of vibration | platform vibration |

Total power | 7.4kw |

Vibration frequency | 4600 (r/min) |

FEATURES AT A GLANCE

The production blocks can be widely used:

coal gangue slag,

sand gravel, aluminum electrolytic copper red slag,

construction waste,

fly ash slag

and other raw materials.

The raw materials are abundant

and can be seen everywhere.

Right elevation

Side elevation

Left elevation

Features of automatic clay brick making machine prices for malawi

1. The machine is designed with reasonable structure and advanced technology. Four vertical axis guidance, upper die push and pull, automatic scraping, reducer lifting mode. Use super vibrating motor to realize vertical directional vibration. The blocks produced are of good quality, high density and high strength.

2. The operation is convenient and flexible, and the performance is comparable to large-scale equipment.

3. The production process is simple, the blocks are naturally maintained, and energy is saved.

Model | QTJ4-45 | Voltage | 220v or customize as your need | ||

Operation | 1-2 person | Power | 2.2kw | ||

Moulding Pressure | 1.5t | Capacity | 1000~1200pcs/8hr | ||

Weight | 200kg | Dimension | 1100*880*1150mm | ||

Normal Brick Size | 400*200*200mm 3pcs/time 390*390*190mm 3pcs/time 390*150*190mm 3pcs/time 390*150*190mm 3pcs/time 390*120*190mm 4pcs/time 240*115*53mm 12pcs/time The mold can be widened or raised according to customer's | ||||

Product Paramenters

Raw materials of

automatic clay brick making machine prices for malawi

Our brick making machine can use the following raw materials to produce high-quality hollow bricks, solid bricks and paving bricks...

1. Cement: 10%~20%;

2. 2. Sand: 30~40%;

3. 3. Crushed stone (<5cm): 30~40%;

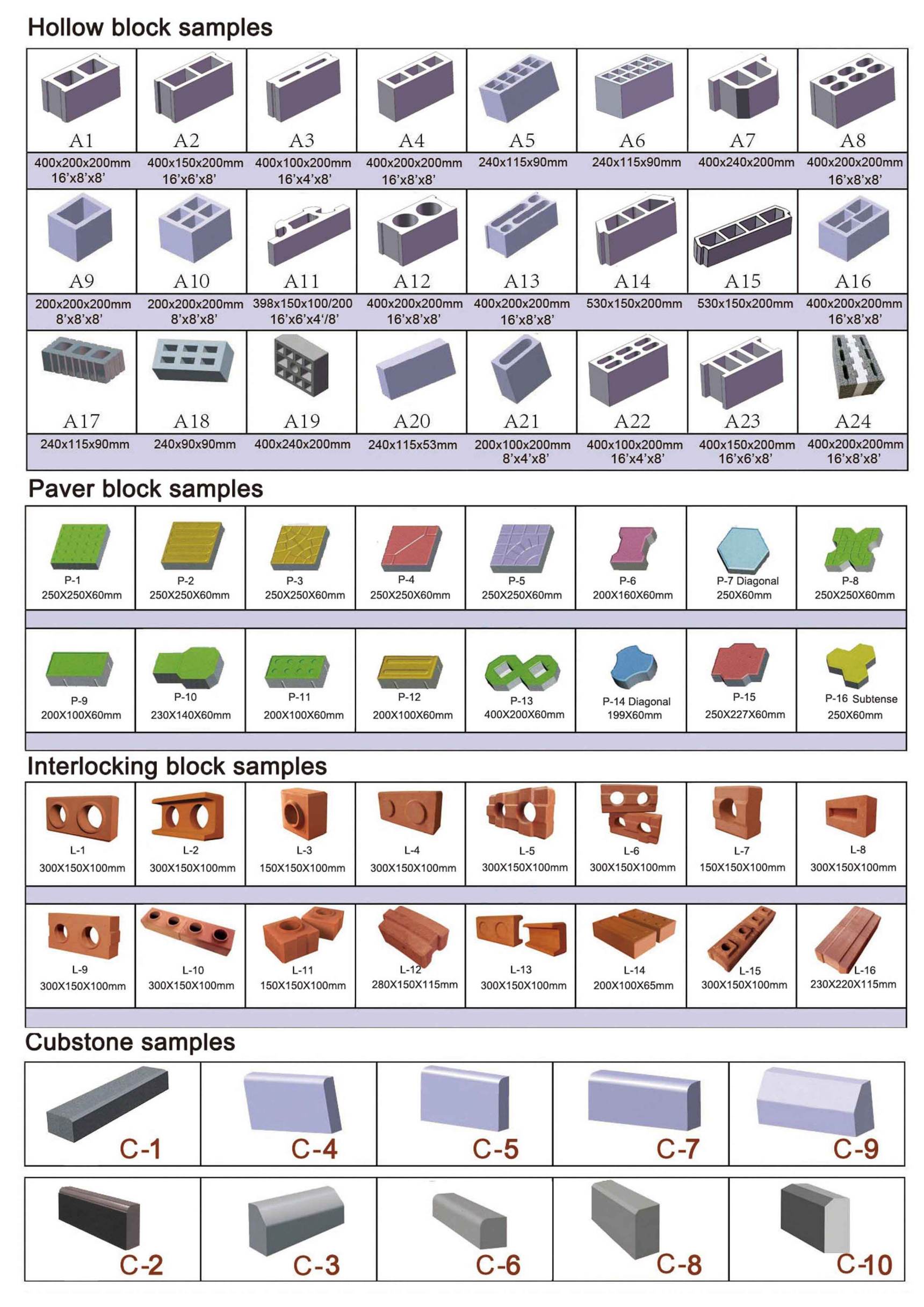

For the shape and size of the bricks.We can customize it according to your needs.The following are common molds for your reference.

Many different size molds for your choose:

The different size brick made by our machine for your reference:

Packing & Delivery

Inner packing of scrap metal crusher machine: plastic packing

Outer packing of scrap metal crusher machine: wooden case or the container

Our company

Gongyi Wanlong Machinery Manufacturing Co., Ltd., located in Gongyi City, Henan Province, is a modern enterprise integrating scientific research, development, manufacturing, sales and export. It has become the most reliable strategic partner in the resource recycling industry. Over the years, the company has been committed to the research and development and production of equipment for the comprehensive utilization of renewable resources, and has always been leading the development direction of the industry, enjoying a high reputation in the industry.

Our Service

Before order:

Answering Customers' Questions: According to our customer's question by email or telephone, we will provide a patient customer' service.

For example: In the beginning of communication, customers will consulting some details about our pellet machine or our company, and we will provide a professional answers for customers understand us better solution just for our customers condition.

Design Drawings: We will design drawings for customers' reference.

Making offer: According to customers purchase quantity, making a good offer with details solutions.

After order:

Delivery Time: After signing the contract and receiving the deposit, the production will take 15~20 working days.

Order Tracking: After the deposit received, there will be a professional team tracking the order from production to package and shipment.

After-sale Service:

Warranty Period: We provide 12 month warranty for main body. Within 12 month, there is any quality problem with the main body(not including the wearing parts), we will arrange our professional engineers to provide requirement service.

Installation Service:

If customers don't need our engineers for installation, we will provide Remote Advisory Services. Also we could arrange engineers to provide installation service if customer need.

FAQ

Q: How about the quality of your products?

A:We put the quality in the first place based on the honesty. Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before the delivery. You can also use Trade Assurance by overseadia for product quality protection, punctual shipment protection and payment protection.

Q: How about the price?

A: We pursue small profits but quick turnover, and we can give you lower price than other trading companies. Besides, customers from overseadia can get a discount. If the product is really suitable and can benefit you, the price is negotiable.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

Q: Can you help chose suitable products?

A: Yes. We have many experts who have worked in this field for many years. They can help you select the most suitable products according to your actual condition. And they can design proper process flow based on your special situation. If necessary, we can even send professionals to your local place for site planning and work-flow design.

Q: When do you deliver the goods?

A:We usually deliver the goods within 10 days depending on detailed product. We will advise the detailed delivery time according to your specific inquiry.

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to solve your problems promptly and thoroughly.

Trading Area

Global