Overview

Product Details

1. Brief introduction of induction heating machine:

Our induction heating machines adopt IGBT series and parallel induction heating technology as the core. Heat the workpiece to a certain temperature, and then cool it rapidly to change its machine structure to achieve some special mechanic properties.

2. Main technical parameters of LSW-60 induction heating machine:

|

Type |

LSW-60 |

|

Power |

60kw |

|

Input current |

90A |

|

Voltage |

3-phase 380V, 50~60 Hz or customized |

|

Oscillation frequency |

18~25KHz |

|

Duty cycle |

100% |

|

Power supply cabinet dimension |

730*550*1030 mm |

|

Transformer cabinet dimension |

460*730*460 mm |

|

Gross weight |

155kg |

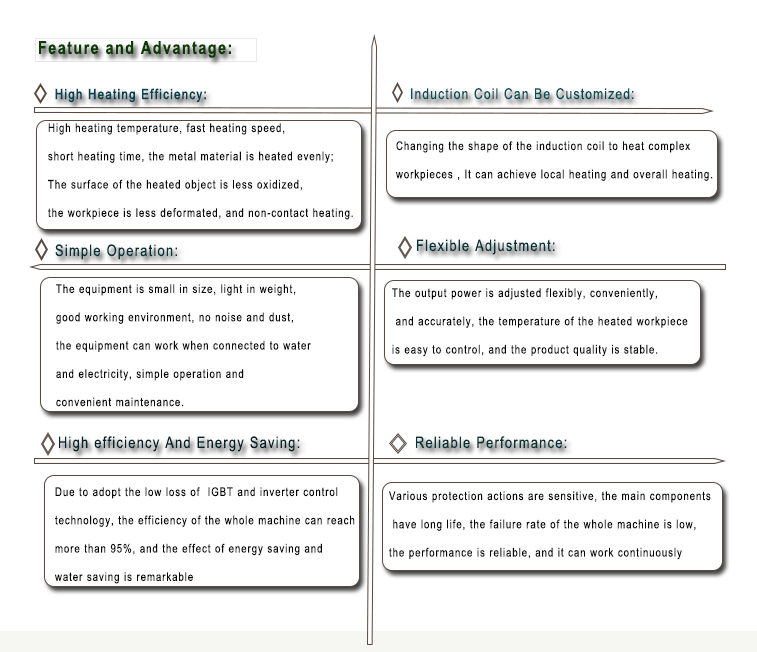

3. Features of induction heating machine:

Suitable for heating steel bars, pipes, plates and angle steels.

(1) Be applicable to heating, brazing, quenching / hardening, etc.

(2) IGBT technology as the core.

(3) Environmentally friendly: no air pollution, no dust and little noise.

(4) Reduced operating cost: high automation, fewer operators needed.

(5) Energy saving: high energy conversion.

(6) High efficiency: Metal can be heated to its desired temperature, even its melting point, instantly.

(7) Duty cycle 100%: can work for 24 hours without a stop.

4. Application of induction heating machine:

(1) Heat treatment: the whole metal or part of metal for quenching, annealing, tempering, diathermy;

(2) Thermoforming: the whole metal or part of metal forging, hot forging, hot rolling;

(3) Welding: brazing metal products, a variety of cutter blade, serrated blade welding, steel / copper welding, the same kind of dissimilar metal welding;

(4) Metal melting: gold, silver, copper, iron, aluminum and other metals (vacuum) melting, casting molding and evaporation coating;

(5) Other applications: semiconductor single crystal growth, heat with bottle sealing, heat sealing toothpaste, powder coating, plastic and other metal implants.

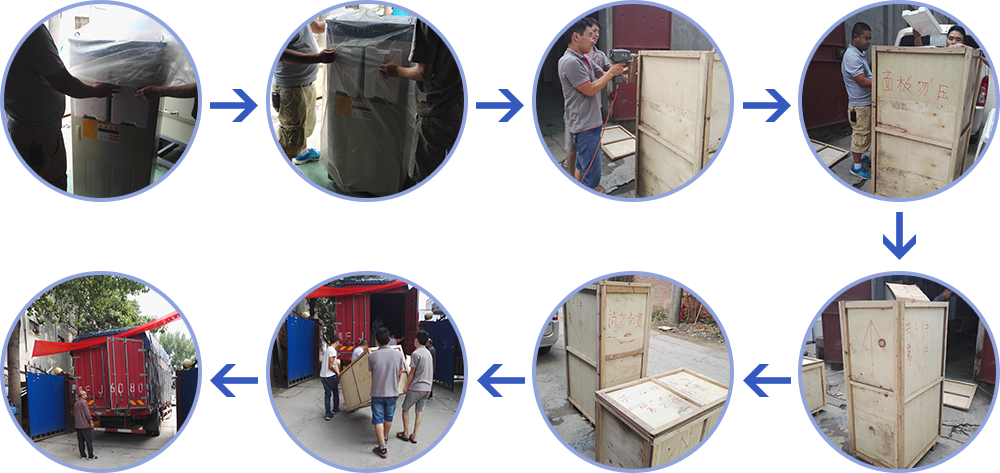

As for packaging: The machine is always wrapped with plastic film for waterproof, and then put into a standard exporting plywood case with foam around for shockproof.

As for shipping:

1. If you have shippers in China, we can send the machines to them for free.

2. If you want us to send the machines to you directly, we can send them to any main port of China promptly.

As a manufacturer with 15 years’ R&D experience in China, we would like to offer any support you need as follows:

1. Immediate reply to your inquiry.

2. Detailed information of our products, and our company if you need.

3. Best quotation.

4. Immediate reply to your questions about our products.

5. Technical support, or alternative accessories if necessary.